Adaptive flexible grinding for complex contoured surfaces, ensuring consistent grinding quality by maintaining constant contact with the workpiece.The constant-force actuator automatically detects posture and compensates for output force with a compensation accuracy within ±0.5N.

Digital and visualized operation with real-time feedback on contact force data, facilitating process tuning.

Plug-and-play compatibility with mainstream robots, addressing ecosystem fragmentation and cross-platform integration challenges.

Applicable for polishing and grinding multi-curved surfaces and various shaped parts made of different materials.

The axial force-controlled floating grinding tool is a highly efficient and flexible active automation deburring tool.

Optimized for complex grinding applications with standard robots, it allows the robot to execute along a radial trajectory while automatically floating in the axial direction. This enhances the robot’s lifespan and trajectory accuracy. It is applicable to multi-process surface treatment operations, including brushing, polishing, cleaning, and deburring.

| Standard accessories list | |||

| Num | Name | Model | Quantity |

| 1 |

100N active floating constant force polishing unit body |

LT-AF100C | 1 |

| 2 |

Force control unit body |

LT-AF100C | 1 |

| 3 | Control cabinet | LT-KZG-A | 1 |

| 4 | Cable/air pipe | 1 | |

| 5 | manual | 1 | |

|

Model |

LT-AF100C |

|

Floating force (N) |

10-100N |

|

Force control accuracy (N) |

±0.5 |

|

Stroke (mm) |

30 |

| Loading capacity (kg) | 3.5 |

| Protection level | IP65 |

| Working temperature(℃) | +5~+45 |

| Air supply (Mpa) | 0.4~0.7(Oil-free, water-free, dust-free 0.03mm) |

| Air consumption (L/min) | 5~10 |

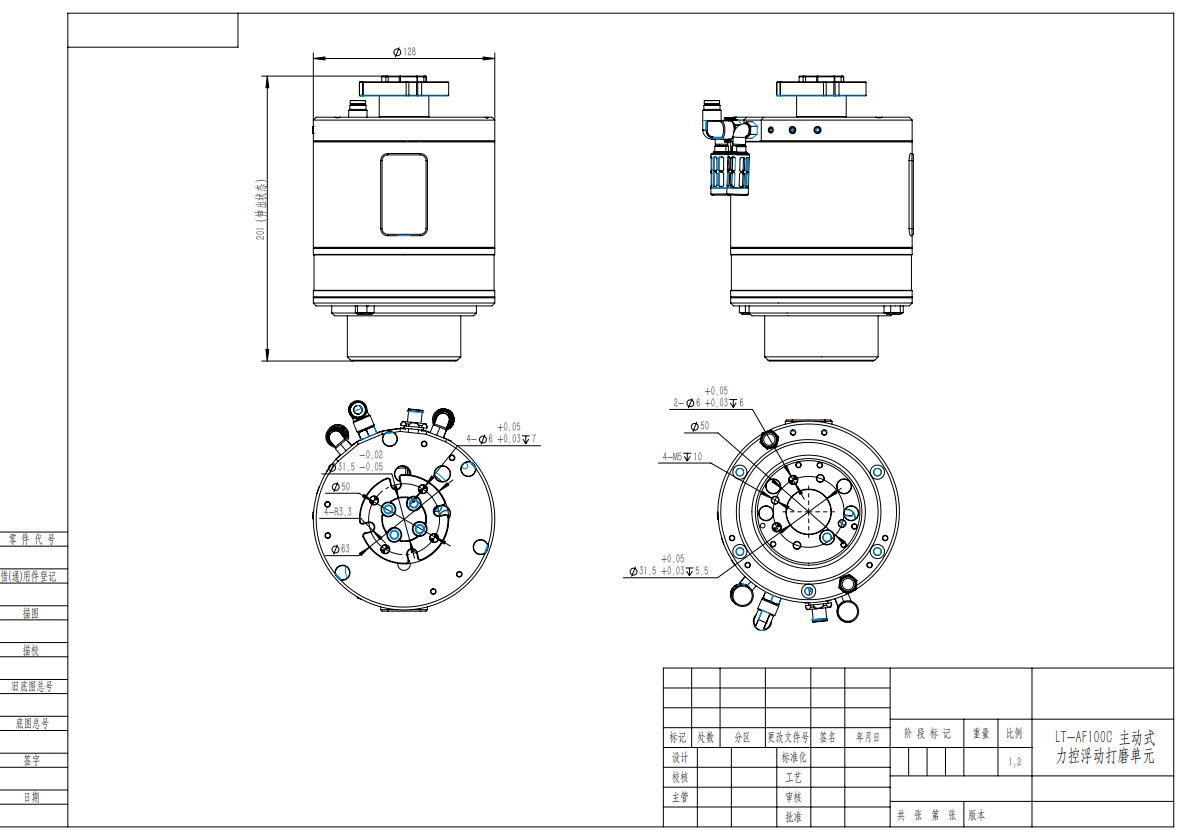

| Dimensions (retracted state, mm) | φ128*171 |

| Dimensions (stretched state, mm) | φ128*201 |

| Weight (kg) | 3.35 |

| Tracheal diameter (mm) | φ6 |

+86 15333867590

Chat online