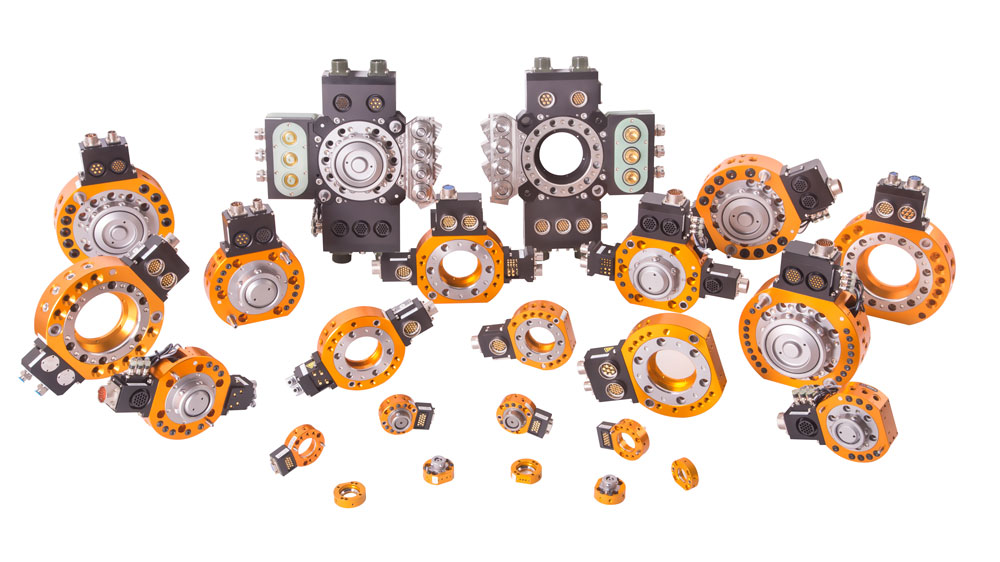

LT robot tool changer is a flexible device that increases the use of multiple or more execution tools by a single industrial robot. The load ranges from 5kg to 2300kg. More than 30 product models are available. The main side is installed on the front arm of the industrial robot, and the tool side is installed on the execution tool, which can automatically and quickly realize the passage of electricity, gas and liquid between the main side and the execution tool. One main side can be used with multiple tool sides to increase the flexible manufacturing of robot production line and the utilization rate of robot.

The LT tool quick change device has the following advantages: the locking mechanism and locating pin are made of high-strength stainless steel, which ensures that the ROBOT TOOL CHANGER can still maintain high accuracy after millions of opening and closing wear; Reliable gas pressure loss protection function; Two proximity sensors are integrated into the main body of the tool quick change device. By detecting the position of the piston, it is determined that the main side of the tool quick change device is locked and opened; Adopt ISO standard installation flange and other advantages. It is widely used for fast switching of end tools such as spot welding pliers, end pick-up, gripper, blanking pliers, laser, burr cleaning tools, vision, ultrasonic welding gun and so on.