Widespread Applications and Challenges of Curved Glass Grinding

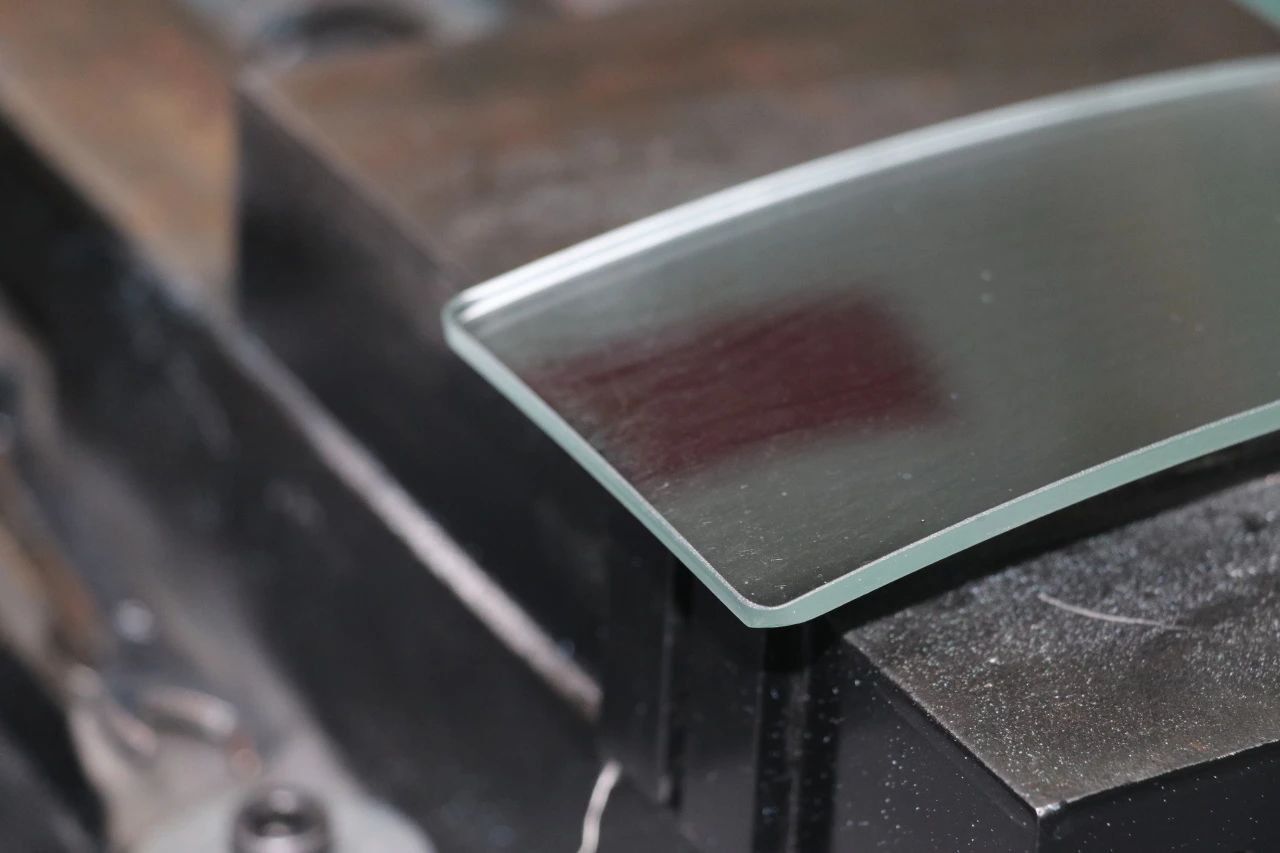

Today, curved glass is widely used in various fields such as consumer electronics, automotive, and optical instruments—for instance, smartphone cover glass and automotive dashboard displays. However, during processing and forming, burrs often appear on the edges and surfaces. For safe assembly and use, precise chamfering is essential. Traditional grinding methods struggle to handle complex curved surfaces, making it difficult to meet requirements for high precision, efficiency, and consistency. The LH-TC Axial Active Constant-Force Floating Grinding and Polishing System provides a solution tailored to these challenges.

II. Customer Pain Points

1. Low Precision with Traditional Grinding:

Irregular curvature makes it difficult for traditional equipment to adapt to surface contours in real time. Burr removal and chamfering often result in over-polishing or under-processing, affecting the appearance, causing scratches and uneven edges, and reducing glass strength.

2. Uncontrollable Grinding Force:

Fixed force settings cannot adjust to different curvatures and material thicknesses. Excessive force may cause edge chipping or breakage; too little force results in poor deburring, longer processing time, high rejection rates, and rising production costs.

3. Low Processing Efficiency:

Manual adjustments to grinding angle and pressure are frequent. Constant reinspection and rework reduce overall line efficiency. Bottlenecks become severe during mass production, delaying order delivery.

III. Solution Overview – LH-TC System Advantages

1. Adaptive Flexible Grinding for Complex Surfaces:

Equipped with high-precision sensors and intelligent control systems, the grinding head automatically adjusts along the surface normal, ensuring close contact and precise handling of various curved burrs and chamfers.

2. Axial Active Constant-Force Control:

The constant-force actuator detects posture and compensates force output automatically, with a compensation accuracy within ±0.5N.

3. Visualized Operation Interface:

A user-friendly control panel allows easy parameter settings and real-time force feedback, simplifying process tuning.

IV. Grinding Results

After a leading consumer electronics company adopted this solution, the curved glass grinding quality improved significantly. The defect rate dropped from 15% to under 3%, visual defects were nearly eliminated, production efficiency increased by 80%, delivery timelines were met, operator count reduced by 30%, labor intensity dropped, and production costs decreased.