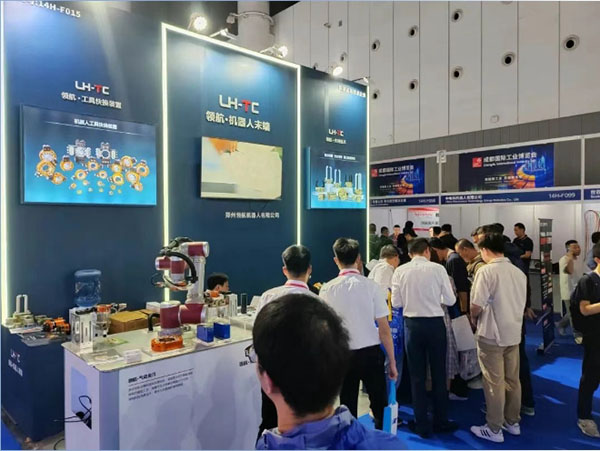

On April 23, the Chengdu International Industrial Fair grandly opened at the Western China International Expo City. LH-TC arrived as scheduled with its core products and innovative automation production solutions, accurately addressing industry pain points and redefining quality benchmarks.

Core Product Showcase

At this year’s Chengdu Industrial Fair, LH-TC Robotics highlighted its industry-leading robotic end-of-arm tool changers and gripping technology solutions. These innovative technologies are widely applied in automotive manufacturing, boosting production efficiency for renowned car brands such as Volvo, Volkswagen, Geely, BYD, and SERES. They also demonstrate outstanding adaptability and innovation value in sectors like 3C electronics, new energy, and aerospace.

During the exhibition, the LH-TC team was interviewed by Sichuan Daily, where they shared how their tool changers, known for high precision, high reliability, and quick response, offer flexible production solutions for industrial automation. They also discussed how their gripping technology enables precise and efficient handling of diverse workpieces, providing a replicable technical path for industrial automation upgrades.

LH-TC · Robotic Tool Changers

-

High-strength alloy steel locking ensures connection precision and safety.

-

Patented material process combined with an angular structure guarantees foolproof locking.

-

Innovative RD connection technology ensures more stable data and signal transmission.

-

Outstanding LT fluid connection technology enables millions of leak-free cycles.

-

Gas pressure loss auto-lock feature ensures safe operations.

-

A full range of tool changers available, with payload options from 5kg to 3000kg.

LH-TC · Gripping Technology

-

Multi-tooth guide rails combined with trapezoidal structure allow higher torque and moment loads.

-

Patented coating technology maintains slider precision even after millions of displacements.

-

Unique self-lubricating design offers extended maintenance-free operation.

LH-TC · Force-Controlled Deburring Tools

-

360-degree radial floating force control adapts to complex part deburring.

-

Patented low-friction structural design ensures tool sensitivity and rapid response.

-

Interchangeable spindle motors (1000–60000 RPM) meet various process requirements.

-

1μm repeatability for precise compensation of workpiece errors.

-

Supports multiple industrial grinding heads to meet specific deburring needs.

-

Axial floating constant-force deburring: self-adaptive for complex surfaces, maintaining active force compensation with ±0.5N accuracy.

High-Energy Onsite, Endless Highlights

Throughout the exhibition, LH-TC’s products demonstrated outstanding efficiency, stability, and safety, earning widespread acclaim from visitors. As the event continues, LH-TC remains committed to delivering even more exciting showcases and experiences with its superior technology and innovative products.

We are at Booth 14H-F015 — we look forward to welcoming you!