Introduction

Pneumatic grippers have become an essential component in the field of robotics, providing efficient and reliable solutions for handling and manipulation tasks in various industries. These grippers, powered by compressed air, are known for their simplicity, cost-effectiveness, and versatility. This article explores the advantages, applications, and recent innovations in pneumatic grippers for robots.

Advantages of Pneumatic Grippers

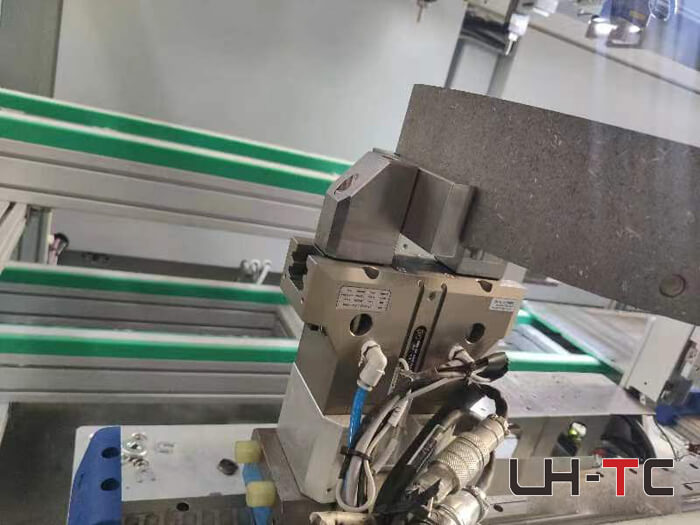

- Simplicity and Reliability: Pneumatic grippers are straightforward in design, making them easy to maintain and repair. The absence of complex electronics reduces the likelihood of malfunction, leading to higher reliability.

- Cost-Effectiveness: Compared to electric and hydraulic grippers, pneumatic grippers are more affordable both in terms of initial investment and operating costs. The use of compressed air, a readily available resource, further reduces operational expenses.

- Lightweight and Compact: These grippers are typically lightweight and compact, making them ideal for integration into robotic systems where space and weight are critical factors.

- Fast and Responsive: Pneumatic grippers offer quick response times, making them suitable for high-speed automation processes. Their ability to exert significant force in a short time frame is a key advantage in applications requiring rapid and precise movements.

Applications of Pneumatic Grippers

- Manufacturing: Pneumatic grippers are widely used in assembly lines for picking, placing, and sorting components. Their ability to handle delicate items without damaging them makes them ideal for tasks involving fragile materials.

- Packaging: In the packaging industry, pneumatic grippers are employed to handle various products, including food, beverages, and pharmaceuticals. Their adaptability allows them to handle items of different shapes and sizes with ease.

- Automotive Industry: Pneumatic grippers play a crucial role in the automotive sector, particularly in the assembly of vehicles. They are used to manipulate parts such as panels, engines, and tires, ensuring precision and efficiency.

- Healthcare and Medical Devices: In the healthcare industry, pneumatic grippers are used in the manufacturing and assembly of medical devices. Their precision and gentle handling capabilities are essential for tasks such as assembling intricate components of medical equipment.

Innovations in Pneumatic Grippers

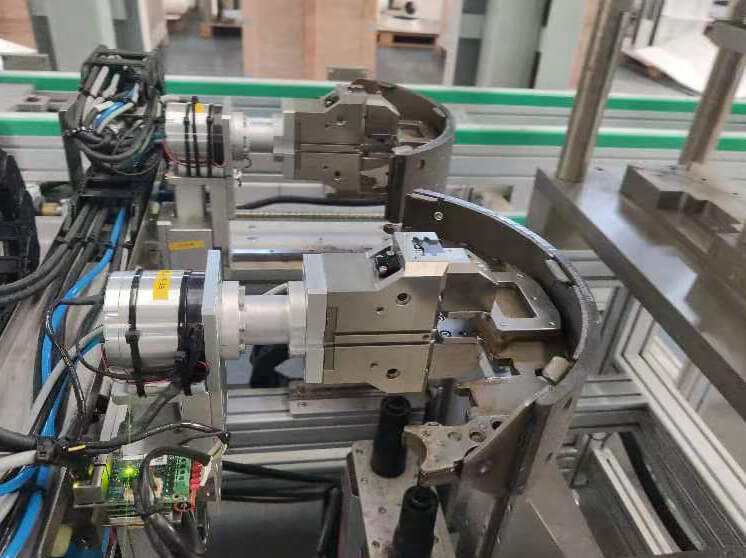

- Smart Grippers: Recent advancements have led to the development of smart pneumatic grippers equipped with sensors and IoT capabilities. These grippers can monitor and adjust their grip in real-time, enhancing accuracy and reducing the risk of errors.

- Adaptive Grippers: Adaptive pneumatic grippers are designed to adjust their gripping force and shape according to the object being handled. This innovation allows robots to handle a wider range of objects without requiring manual adjustments.

- Energy-Efficient Designs: Newer pneumatic grippers are being designed with energy efficiency in mind, utilizing less compressed air while maintaining performance. This not only reduces operating costs but also contributes to sustainability efforts in industrial processes.

Conclusion

Pneumatic grippers continue to be a vital tool in the robotics industry, offering a balance of simplicity, cost-effectiveness, and performance. As technology advances, the capabilities of these grippers are expanding, opening up new possibilities for automation in various sectors. The future of pneumatic grippers looks promising, with innovations focusing on smart technology, adaptability, and energy efficiency.