In the world of automation, the pneumatic parallel gripper stands out as a crucial component, offering precision and reliability in various industrial applications. This article delves into the workings, advantages, and applications of pneumatic parallel grippers.

Introduction

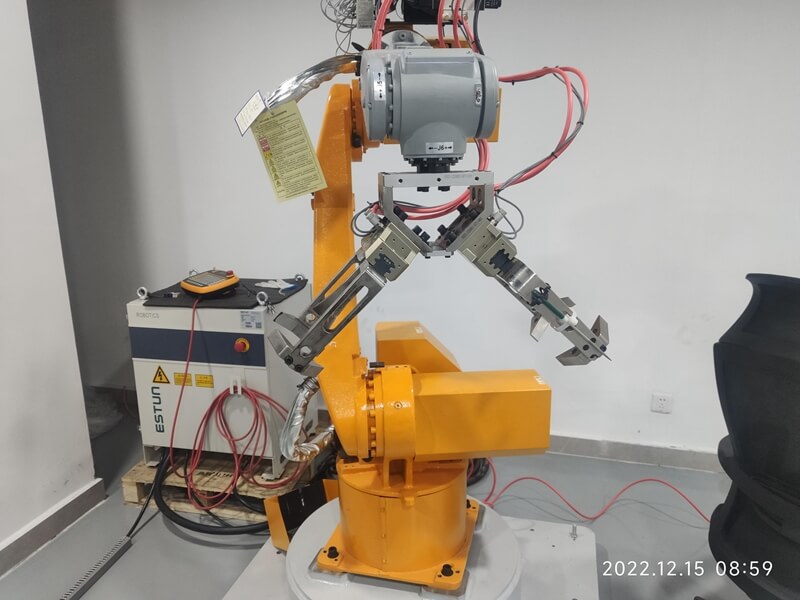

Pneumatic parallel grippers are a type of robotic end effector that use compressed air to open and close their jaws, or fingers, in a parallel motion. This parallel motion ensures that the object being gripped is held securely and evenly, which is essential for tasks that require high precision.

How It Works

The gripper operates through a pneumatic system, where compressed air is directed into cylinders that drive the movement of the gripper jaws. These jaws move simultaneously and in parallel, which makes them ideal for handling objects of various shapes and sizes. The primary components of a pneumatic parallel gripper include:

- Cylinders: These are the powerhouses that convert compressed air into mechanical motion.

- Jaws: The gripping elements that come into direct contact with the object.

- Valves: Control the flow of air into the cylinders, thus controlling the movement of the jaws.

- Sensors: Often used to provide feedback on the position and force of the grip.

Advantages

- Simplicity and Reliability: Pneumatic systems are relatively simple compared to electric or hydraulic systems, making them reliable and easy to maintain.

- Cost-Effective: Pneumatic grippers are generally less expensive to produce and operate.

- Speed and Precision: They offer quick response times and precise control, which is crucial for high-speed automation processes.

- Adaptability: Can handle a wide range of objects with varying weights and shapes.

Applications

Pneumatic parallel grippers are widely used in industries such as:

- Manufacturing: For assembly line tasks, picking and placing components, and machine tending.

- Packaging: Handling products for packing, palletizing, and sorting.

- Automotive: Assisting in the assembly of automotive parts and components.

- Electronics: Handling delicate electronic components during assembly processes.

Conclusion

Pneumatic parallel grippers are an essential part of modern automation, offering a blend of simplicity, efficiency, and precision. Their widespread use across various industries highlights their versatility and importance in enhancing productivity and ensuring reliable operations.