The pneumatic shaft gripper is an essential tool in modern industrial automation, offering precision, reliability, and efficiency in material handling processes. This device plays a crucial role in various industries, where it is used to secure, lift, and transport shafts or cylindrical objects with the help of compressed air. The pneumatic shaft gripper is designed to handle objects of different sizes and weights, making it highly versatile for applications in manufacturing, packaging, and assembly lines.

One of the key advantages of the pneumatic shaft gripper is its ability to provide consistent gripping force, which ensures the safe handling of sensitive or delicate materials. This is particularly important in industries like electronics and automotive manufacturing, where precision and care are paramount. The gripper’s design allows for quick and easy adjustments, enabling operators to switch between different tasks with minimal downtime. Additionally, the use of compressed air as the driving force makes the pneumatic shaft gripper an energy-efficient and environmentally friendly option compared to other gripping mechanisms.

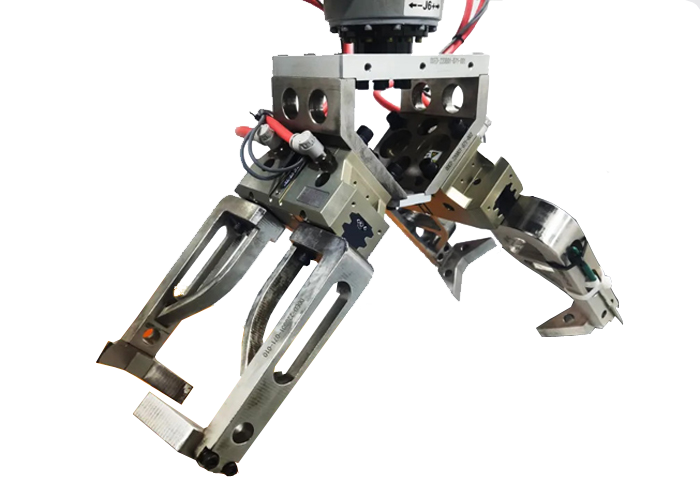

In manufacturing processes, the pneumatic shaft gripper is often used in conjunction with robotic arms and other automated systems, enhancing the overall efficiency of production lines. Its ability to handle a wide range of materials, from metals to plastics, further extends its applicability across different sectors. For instance, in the printing industry, the gripper is used to manage rolls of paper or film, ensuring precise alignment and tension during the printing process. Similarly, in the packaging industry, it aids in the automated handling of products, improving speed and accuracy in operations.

Maintenance of the pneumatic shaft gripper is relatively straightforward, as its components are typically durable and require minimal servicing. The simplicity of its design also means that replacements and repairs can be done quickly, reducing downtime and maintaining productivity. As industries continue to evolve and adopt more automated solutions, the demand for reliable and versatile tools like the pneumatic shaft gripper is expected to grow.

In conclusion, the pneumatic shaft gripper is a vital component in modern industrial settings, offering unparalleled versatility and efficiency. Its ability to handle a variety of materials, combined with its energy-efficient operation and ease of maintenance, makes it an indispensable tool in the automation of material handling processes. As industries advance and automation becomes increasingly integrated into production lines, the pneumatic shaft gripper will continue to play a pivotal role in ensuring smooth and efficient operations.