In the vast system of modern industrial manufacturing, the deburring process plays a crucial role in the quality and performance of products. This is particularly true when dealing with multi-surface component processing, where traditional deburring methods often face numerous challenges.

As the manufacturing industry continues to evolve, the demand for precision and surface quality in components across various sectors is becoming increasingly stringent. The automotive industry seeks smoother appearances and more reliable performance, the aerospace sector requires highly precise components to ensure flight safety, and the medical device industry maintains almost stringent standards for the cleanliness and quality of its parts.

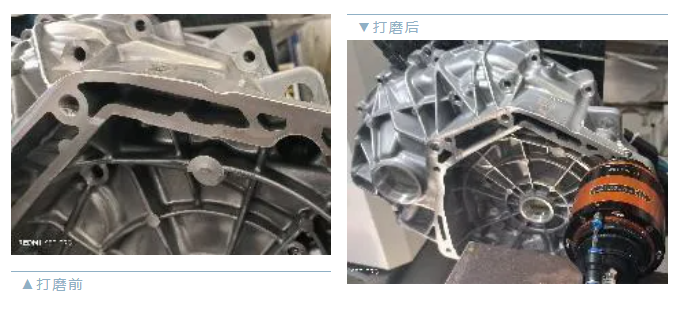

Against this backdrop, the floating deburring from Pioneer Robotics stands out. Its unique 360° radial floating characteristic allows it to perfectly adapt to the complex shapes of multi-surface components, providing comprehensive and thorough deburring. This adaptive processing capability significantly improves deburring efficiency and effectiveness, ensuring smooth and flat surfaces on components.

The advantage of segmented floating power control and interactive data enables precise adjustment of floating parameters according to different workpieces and processing requirements, achieving highly adaptable processing solutions. Additionally, its ability to absorb product deformation effectively reduces debugging difficulty, making it adept at handling various materials and shapes. The flexible contact between the tool and the workpiece not only prevents over-cutting but also reduces damage to the workpiece, ensuring processing accuracy and safety.

In practical applications, the floating deburring has demonstrated its exceptional value across numerous fields. Whether in the manufacturing of automotive components, the processing of critical aerospace parts, or on the production lines of medical devices, its busy and efficient presence can be seen.

Pioneer Robotics is committed to the continuous development and innovation of floating deburrings, constantly enhancing product performance to better meet the evolving demands of industrial manufacturing. In the future, the floating deburring is expected to continue contributing to the advancement of industrial manufacturing, becoming an indispensable part of the industry.