In today’s rapidly evolving industrial landscape, the quest for enhanced productivity and operational efficiency is relentless. One technological advancement that has made a significant impact in this realm is the development of end-effector quick-change devices for robots. These devices are designed to facilitate the rapid swapping of tools or grippers on robotic arms, thereby minimizing downtime and maximizing throughput. This article delves into how these innovative devices contribute to increased production efficiency and their broader implications for the manufacturing sector.

The Mechanics of Quick-Change Devices

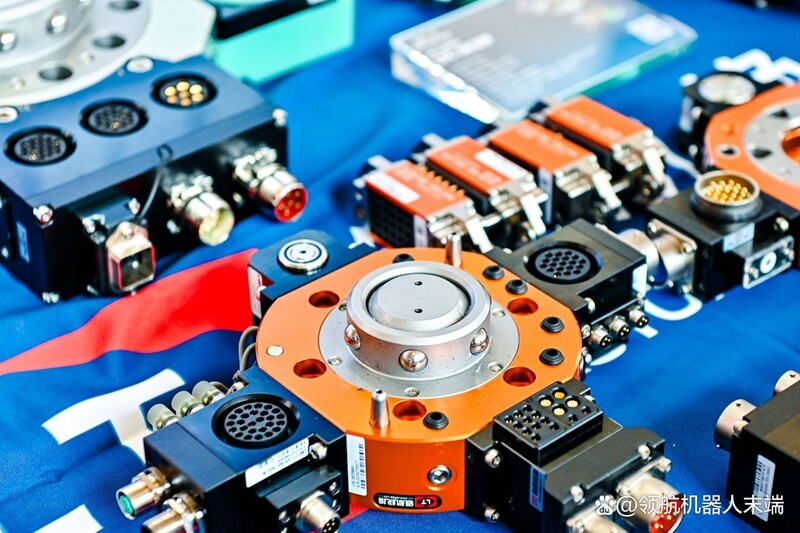

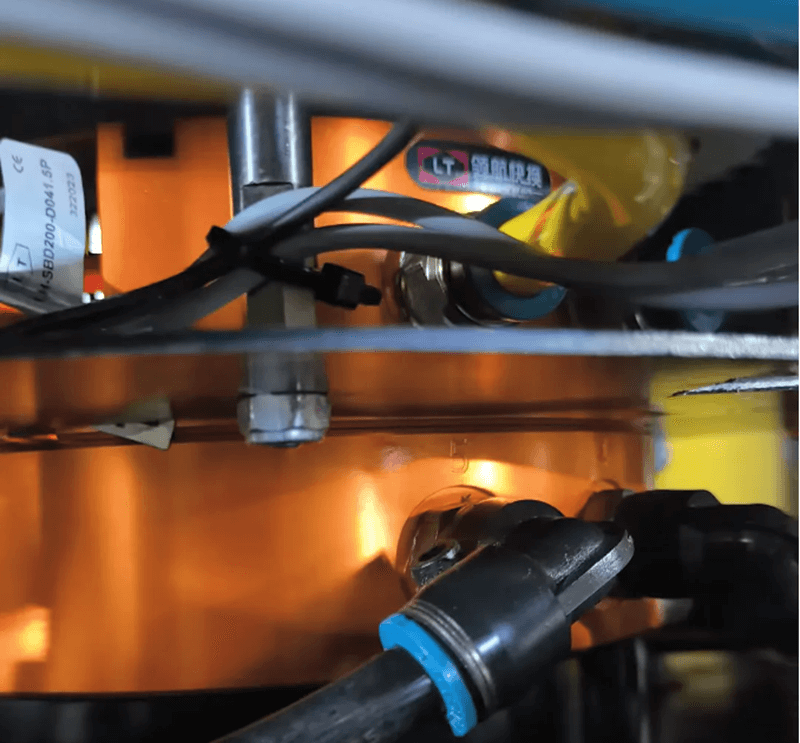

An end-effector quick-change device is a mechanism that allows robots to switch between different tools or grippers quickly and automatically. Traditionally, changing the end-effector on a robotic arm required manual intervention, which could be time-consuming and prone to errors. With a quick-change device, the process is streamlined: the robot can release one tool and attach another within seconds, often without any human involvement. This is achieved through precise mechanical interfaces and secure locking mechanisms that ensure the new tool is correctly aligned and ready for use.

Enhancing Production Efficiency

The primary advantage of using quick-change devices is the significant reduction in downtime. In a production environment, every second counts, and the ability to swiftly change end-effectors means that robots can transition between tasks more seamlessly. For example, in an automotive assembly line, a robot might need to switch between welding, painting, and assembly tools. With a quick-change device, these transitions happen almost instantaneously, keeping the production line moving smoothly and efficiently.

Moreover, quick-change devices enhance the flexibility of manufacturing systems. Factories can handle a wider variety of products without extensive reconfiguration. This adaptability is crucial in industries where customization and small batch sizes are becoming increasingly common. By minimizing the time and effort required to retool, companies can respond more rapidly to market demands and reduce the cost associated with product changes.

Cost Savings and Return on Investment

Implementing end-effector quick-change devices can lead to substantial cost savings over time. Reduced downtime directly translates to higher productivity and lower labor costs since fewer manual interventions are needed. Additionally, the increased efficiency and flexibility can lead to better utilization of existing robotic systems, potentially delaying the need for expensive new equipment investments.

The return on investment (ROI) for quick-change systems can be quite favorable. While the initial cost of these devices might be higher compared to traditional setups, the ongoing savings from reduced downtime and increased productivity often offset this initial expenditure. Companies that adopt these technologies can expect to see improvements in their bottom line relatively quickly.

Broader Implications for the Manufacturing Sector

The adoption of quick-change devices is part of a broader trend towards more agile and flexible manufacturing systems. As Industry 4.0 and smart factories continue to evolve, the ability to quickly adapt to new processes and products will become even more critical. Quick-change devices are a key component of this flexibility, enabling more efficient use of robotic systems and facilitating the integration of advanced manufacturing techniques such as additive manufacturing and collaborative robotics.

Furthermore, these devices support the trend towards increased automation and the reduction of manual labor in hazardous or repetitive tasks. By enabling robots to handle a wider range of tasks with minimal downtime, quick-change devices help create safer and more efficient workplaces.

Conclusion

End-effector quick-change devices represent a significant advancement in robotic technology, offering substantial benefits in terms of production efficiency, flexibility, and cost savings. As industries continue to seek ways to enhance productivity and stay competitive in a global market, the adoption of these devices is likely to become increasingly widespread. By reducing downtime and enabling more agile manufacturing processes, quick-change devices are set to play a crucial role in the future of industrial automation.