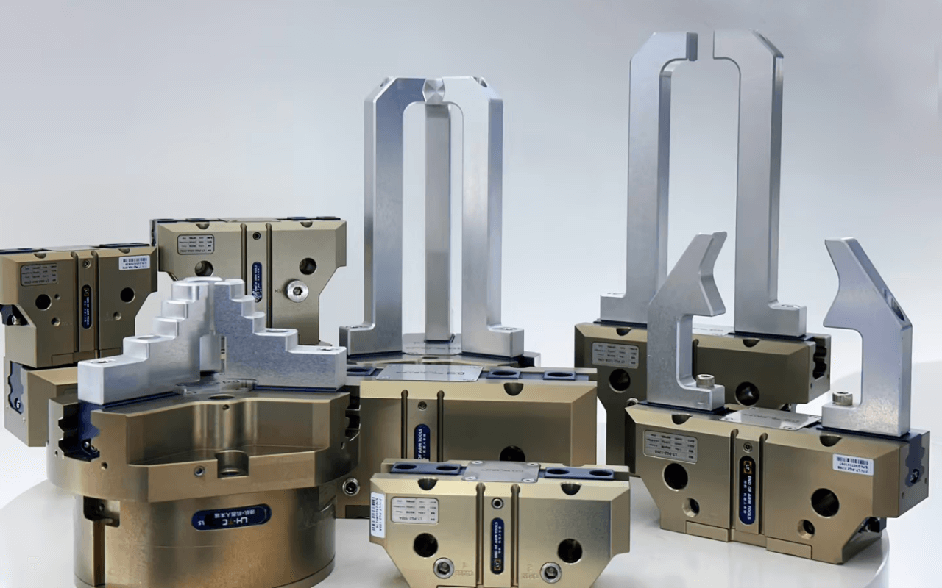

In industrial automation, robotic end-effectors serve as the critical interface for interaction between robots and their environment, handling tasks such as gripping, transporting, and placing workpieces. Among these, dustproof grippers, high-temperature resistant grippers, and force-maintaining grippers stand out as essential end-effector types due to their unique features and advantages. LH-TC provides a detailed analysis of these three types of grippers to help better understand their value in different application scenarios.

Dustproof Grippers

Dustproof grippers offer superior dust-resistance performance, providing a durable and reliable solution for gripping and handling workpieces in precision manufacturing and harsh environments. These grippers use high-performance sealing materials and high-precision mechanical designs to ensure the internal mechanical structure remains clean and lubricated, even in dust- and debris-laden conditions, significantly extending the robot’s lifespan.

Dustproof grippers prevent the infiltration of fine particles into the joints, avoiding clogs or wear that could degrade accuracy. This ensures consistent gripping force and precision over time. Additionally, they are highly adaptable and flexible, capable of handling workpieces of various shapes and weights, thereby enhancing the production line’s flexibility and automation. Equipped with intelligent control systems, dustproof grippers can automatically optimize gripping strategies based on workpiece characteristics, improving operational efficiency and product quality.

Force-Maintaining Grippers

Force-maintaining grippers, also known as force-controlled grippers, focus on maintaining stable gripping force during operation to ensure the workpiece’s stability. These grippers are typically driven by electric or hydraulic systems, enabling precise adjustments to gripping force to accommodate workpieces of varying weights and materials.

During operation, force-maintaining grippers can detect changes in gripping force in real time and adjust through feedback mechanisms to ensure the force remains within a safe range. They excel in scenarios requiring precise gripping force control, such as assembly and material handling, significantly improving production efficiency and product quality.

Comparison and Applications

Each type of gripper has its unique advantages and application scenarios:

- Dustproof grippers are ideal for long-term use in harsh environments, maintaining gripping accuracy and stability.

- High-temperature resistant grippers are suitable for high-temperature operations, performing reliably under extreme conditions.

- Force-maintaining grippers are tailored for applications requiring precise gripping force control.

When selecting robotic end-effectors, it’s essential to consider the specific application and requirements to choose the most suitable gripper type, achieving optimal production efficiency and product quality.