On August 8th, 2022, Mobile Industrial Robots (MiR), a pioneer in the global mobile robot market, and Modula, a manufacturer of intelligent storage solutions, jointly released a new automated storage, picking, and material handling solution for the global market.

This fully automated system is suitable for transporting items in designated areas within warehouses, production workshops, distribution centers, and other scenarios, and will significantly reduce the dependence on labor in related work in the past, aiming to help more enterprises achieve the transformation to “lights-out factory”. The system supports four configurations: semi-automatic picking of single items, semi-automatic picking using sorting trolleys, full-automatic picking of single items, and full-automatic box picking. Customers can choose according to their needs to achieve full or partial automation of material handling. This is also an important software capability expansion for MiR after the release of robot software updates in the second quarter of this year.

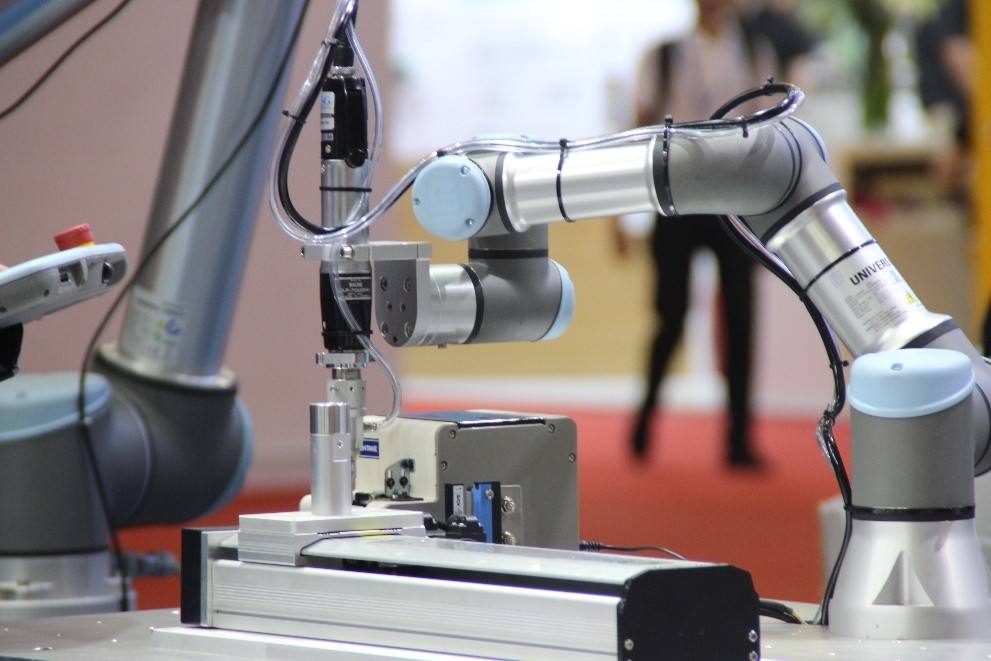

As we know, as an important branch of industrial robots, collaborative robots’ safety, flexibility, ease of use, and other characteristics make them complementary to many traditional industrial robots’ service gaps in the industrial field, becoming an important part of the industrial production process from full manual to full mechanical.

Currently, China’s small and medium-sized enterprise market is enormous, with almost 70% of companies belonging to this sector. Deploying convenient plug-and-play robot tools will be very suitable for these companies’ production processes, making the future of collaborative robots full of opportunities.

It is worth noting that in addition to the industrial manufacturing sector, collaborative robots have rapidly extended to “non-industrial” application scenarios in recent years. Non-industrial sectors such as catering, medical health, education, and new retail have become the main driving force for the growth of collaborative robot market. The non-industrial field has become a blue ocean market for collaborative robot applications, and various segmented fields have emerged one after another as demand diversifies. This has greatly expanded the growth space for collaborative robots, and many industry experts believe that collaborative robots will become the new favorite of machine-enabled manufacturing.

As a market innovator, MiR can produce highly reliable Autonomous Mobile Robots (AMRs) and is committed to optimizing internal logistics efficiency and productivity. All of this stems from MiR’s clever grasp of collaboration, adaptability, and performance.

Zhang Yu, the China Sales Director of MiR’s Autonomous Mobile Robots, said, “The launch of the new system is a great testament to MiR’s software compatibility and openness. In addition, our robots can perform logistics functions with both hands and feet, breaking through the functional limitations of traditional logistics robots and helping customers to release more manpower and save more production time.”

For manufacturing, the key task of automation is to keep up with the strong demand for manufacturing processes, thereby improving the overall level of intelligence in the entire chain.

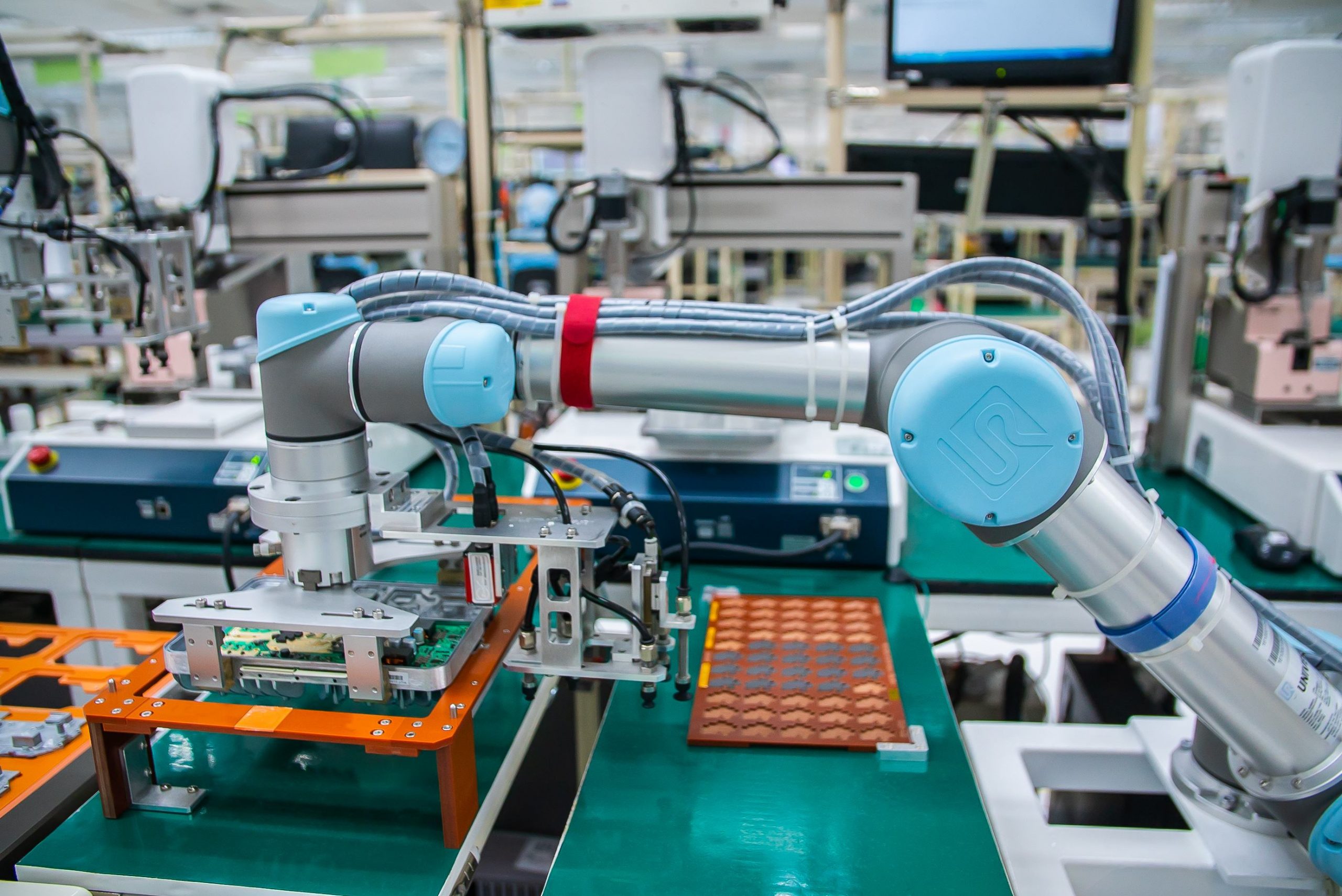

According to the International Federation of Robotics, the electronics manufacturing industry has surpassed the automotive manufacturing industry globally and become a major application industry for industrial robots. MiR’s autonomous mobile robots can be deployed throughout the entire electronics manufacturing supply chain, including upstream materials and equipment manufacturing, midstream module manufacturing, and downstream branded products. By automating production line logistics transportation, dependence on “people” for component transportation can be reduced, improving speed and accuracy. MiR robots can help electronics manufacturing companies solve the following main pain points: production refinement, fragmentation, and diversification; short delivery cycles; C2B driving companies to “produce according to demand”; strict environmental requirements for electronic component production such as dust, cleanliness, and anti-static; and long-term labor shortages in manufacturing, which squeeze profit margins.

MiR believes that in addition to hardware configuration, successful completion of automation tasks by collaborative mobile robots depends on software capabilities. When considering a robot’s software capabilities, three aspects should be considered: first, the robot’s own operating software; second, the management software of the robot fleet; and third, the open compatibility of robot software, which is the adaptation with other software such as data monitoring, security monitoring, and warehouse management.

Whether it is electronics component manufacturing, fast-moving consumer goods retail, warehousing logistics, or automotive manufacturing, the deployment of collaborative mobile robots requires optimization in three aspects simultaneously: people, efficiency, and cost. This means that AMRs must have accurate and safe task execution capabilities, an open ecosystem, and flexible and scalable functional characteristics. All three aspects are essential.

Zhang Yu stated, “Software capability is the next watershed of AMR technology and an important part of determining the intelligence of collaborative mobile robots. MiR’s focus this year is to further iterate on existing software products and prepare for integration into larger industrial deployments.”