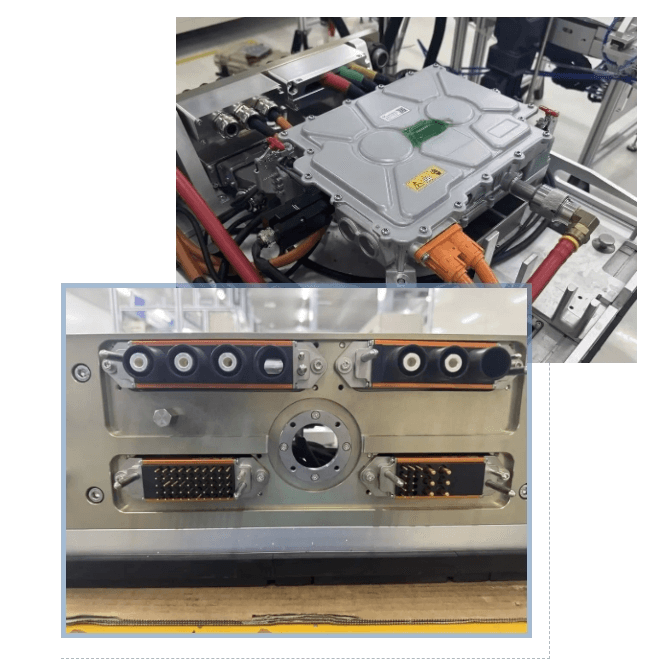

With the rapid development of the new energy vehicle (NEV) manufacturing industry, the assembly and testing of core components such as electric drives and power batteries have become the heart of production. As the market enters a growth phase, powertrain and component manufacturers urgently need advanced manufacturing processes and technologies to enhance their competitiveness.

As a leading company in the energy connection industry, LH-TC provides highly efficient connection solutions for the automated end-of-line testing of NEV core components, including integrated electric drive assemblies, motors, motor controllers, and power batteries. These solutions ensure high production line efficiency and equipment availability, helping customers achieve high production capacity. We have already delivered successful solutions to several well-known automobile manufacturers.

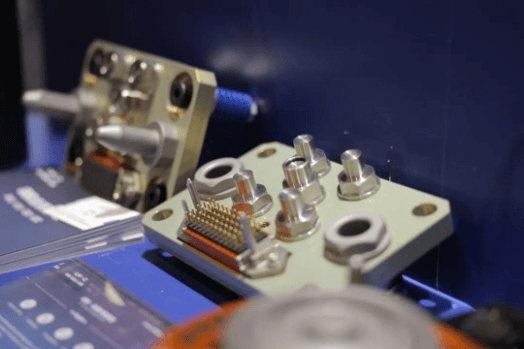

Energy Docking Combination Plate

The Energy Docking Combination Plate integrates various connection types—power, signal, data, optical fiber, pneumatic, and fluid—into a compact frame or housing. It offers space-saving benefits, high current-carrying capacity, and long service life while maintaining stable and reliable connections even under the harshest mechanical and environmental conditions. This solution is applicable across multiple industries, including automotive manufacturing, robotics, test and inspection equipment, automated production systems, railway battery connection systems, and other industrial fields.

Advantages of the Energy Docking Combination Plate

- Stable Operation: High stability and reliability, with all contact pins gold- or silver-plated for durability. Capable of over 100,000 mating cycles. Strong current-carrying capacity and resistance to vibration and impact.

- Ultra-High Mating Durability: The Linghang power module achieves up to one million repeated insertions and removals, meeting customer demands for high-power, high-voltage, and high-cycle testing connections.

- Leak-Free Fluid Transmission: Unique sealing technology effectively prevents fluid leakage, ensuring disconnection without spillage. Unaffected by water quality, it guarantees the safety of both fluid and electrical connectors during simultaneous operation.

- Efficient Operation: Simultaneous connection of all circuits significantly reduces operation time and improves efficiency.

- Prevents Misconnections: All circuits, including electrical ones, have fixed and unique positions, effectively eliminating the risk of incorrect connections.

The LH-TC Energy Docking Combination Plate enables synchronized energy circuit connections while fully meeting diverse industrial and application requirements. Its all-in-one design enhances production process efficiency and safety. With ongoing technological advancements, the LH-TC Energy Docking Combination Plate will play an increasingly vital role in future energy transmission systems.