Pneumatic grippers, as a key technology in automation, are driving robotic grasping technology to a new stage of development.

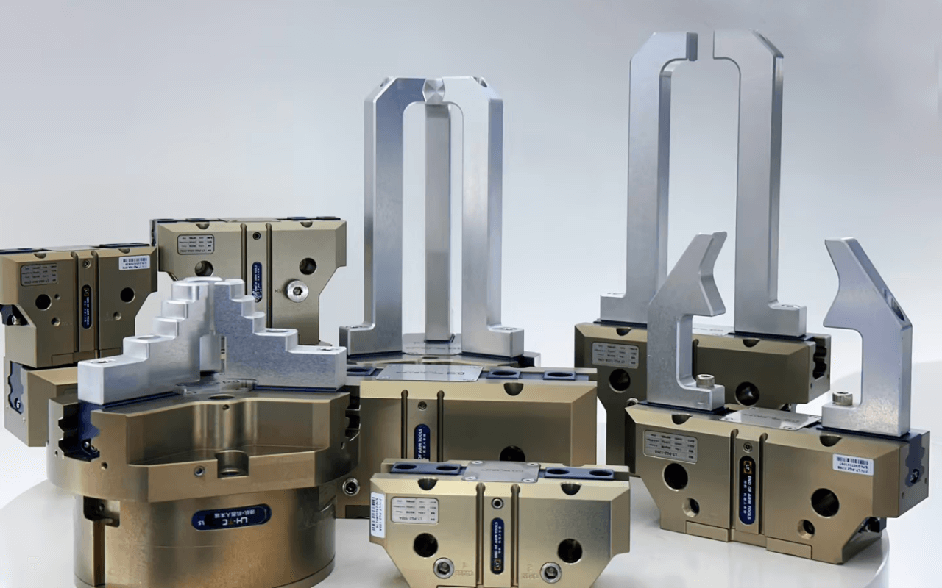

Utilizing pneumatic transmission principles, pneumatic grippers control the opening and closing of the jaws by regulating air pressure. Compared to traditional electric or hydraulic grippers, pneumatic grippers offer advantages such as a simple structure and rapid response speed. More importantly, their flexible grasping method enables them to handle objects of various shapes, sizes, and materials with ease, greatly enhancing the adaptability and flexibility of robots.

In the field of industrial automation, pneumatic grippers have vast application prospects. In industries such as automotive manufacturing, electronics production, and food processing, they are widely used in material handling, assembly, and packaging automation. Their efficient grasping capability and precise positioning accuracy not only significantly improve production efficiency but also effectively reduce the risks and costs associated with manual operations.

Additionally, the flexible grasping method of pneumatic grippers provides strong support for the development of collaborative robots. Since collaborative robots work alongside humans in shared spaces, their gripping devices must ensure high safety and reliability. Pneumatic grippers’ soft-touch approach allows them to securely grasp objects without causing damage, thereby ensuring the safety and reliability of collaborative robots.

The emergence of pneumatic gripper technology marks a new phase in robotic grasping technology. In the future, with continuous technological innovations and the expansion of application areas, pneumatic grippers will become an indispensable part of industrial automation.