With the development of my country’s economy, the increase of residents’ income, and the expansion of housing area, the demand for furniture market is also increasing. As a mainstream furniture product, wooden furniture has also ushered in a new round of development opportunities.

There are generally three ways to sand wood furniture: dry sanding, wet sanding and mechanical sanding. Generally, in large-scale construction, in order to improve work efficiency, mechanical grinding will be used.

Case Background

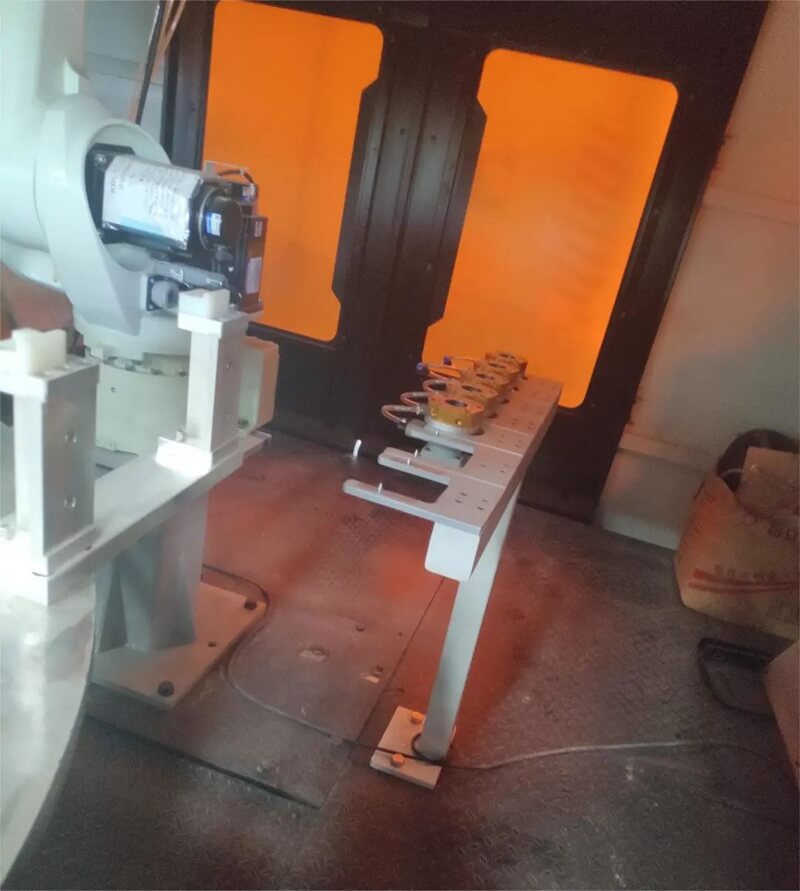

A furniture company in Jiangxi, mainly engaged in furniture manufacturing, furniture sales, door and window manufacturing and processing. In the process of producing wooden furniture, robots are used for grinding, and different grinding tools need to be switched when grinding different surfaces.

Solution

In view of the situation that the company needs to switch grinding tools frequently, the pilot technicians recommend the use of LTC-0040A end effector change + 15-core signal module. LTC-0040A end effector change effectively solves the problems the company encountered in sanding wooden furniture, and increases the finish and brightness, thereby improving production efficiency.