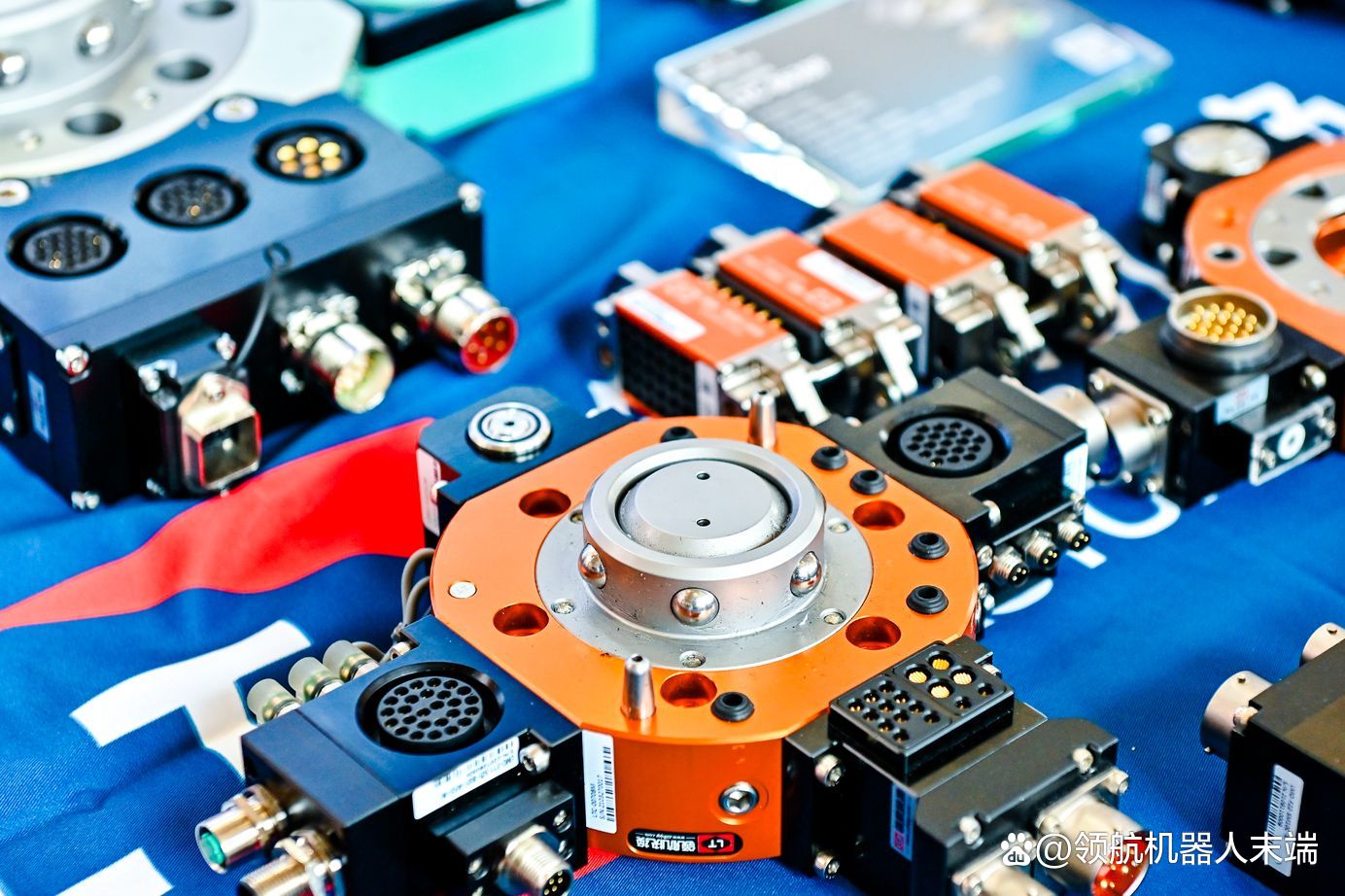

In today’s highly automated industrial sector, the importance of robotic end-effectors is becoming increasingly prominent. Among them, quick-change discs, with their unique advantages and wide applications, have become a key force driving the development of the industry.

The primary feature of quick-change discs is their strong versatility. They can be adapted to most brands of industrial robots without worrying about the compatibility issues of end tools, greatly improving the compatibility and flexibility of the equipment. From light tasks with a load of 5KG to heavy-duty operations with a load of 3000KG, quick-change discs can handle them with ease, meeting the production needs of various scales and types.

In the application scenarios of end tools such as spot welding guns, quick-change discs show unparalleled advantages. They enable a single robot to automatically switch between multiple end tools, greatly improving production efficiency. In the past, changing end tools could take a lot of time and manpower, but now, with quick-change discs, this process has become fast and convenient. Workers can complete the tool change in a short time with simple operations, allowing the robot to quickly switch to new tasks.

The high repeatability of quick-change discs is also an important advantage. This ensures the accuracy of the position and operational stability after each tool change, thereby ensuring the quality and consistency of the products. Whether in large-scale production or processes requiring high precision, quick-change discs can reliably perform their functions.

In addition, they have a series of safety features. The self-locking function of pressure loss ensures the safety of the robot and tools in case of accidents, the safety docking system further enhances stability, and the arc extinguishing module effectively prevents electrical faults. These features jointly provide comprehensive safety guarantees for the production process.

Quick-change discs are widely used in the automotive manufacturing industry. They can quickly switch between different welding tools to meet the production needs of different models and components. At the same time, in fields such as electronics manufacturing and metal processing, quick-change discs also play an important role, helping enterprises achieve efficient, flexible, and safe production modes.

With the continuous advancement of Industry 4.0, the requirements for robotic end-effectors will become higher and higher. As a key component, quick-change discs will continue to play their important role, continuously innovate and evolve, bringing more efficient and intelligent production solutions to various industries. Zhengzhou Linghang Robotics Co., Ltd., as a leading company focusing on robotic end-effectors, will continue to be committed to the development and promotion of quick-change disc technology, contributing to the development of the industry.

Let’s look forward to more exciting performances of quick-change discs in the future and witness the changes and progress they bring to the industrial sector!