Today, Linghang Robot unveiled its robot tool changers, spot welding gun changers, pneumatic quick connectors, force control deburring tools, pneumatic grippers, and energy docking combination boards, along with related automation production innovative solutions, at the 19th AMTS Shanghai International Automotive Manufacturing Technology & Material Show. This comprehensive display showcased the endless charm of cutting-edge technology in the robot end-tooling industry.

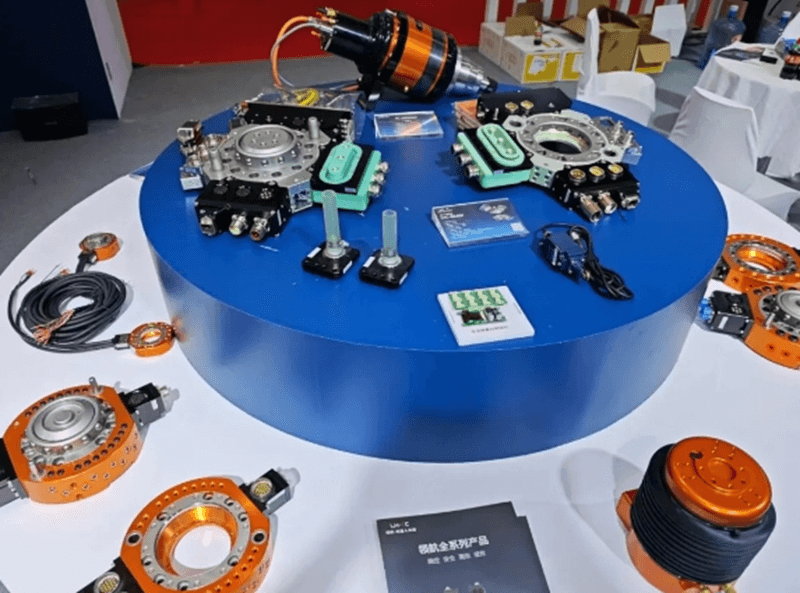

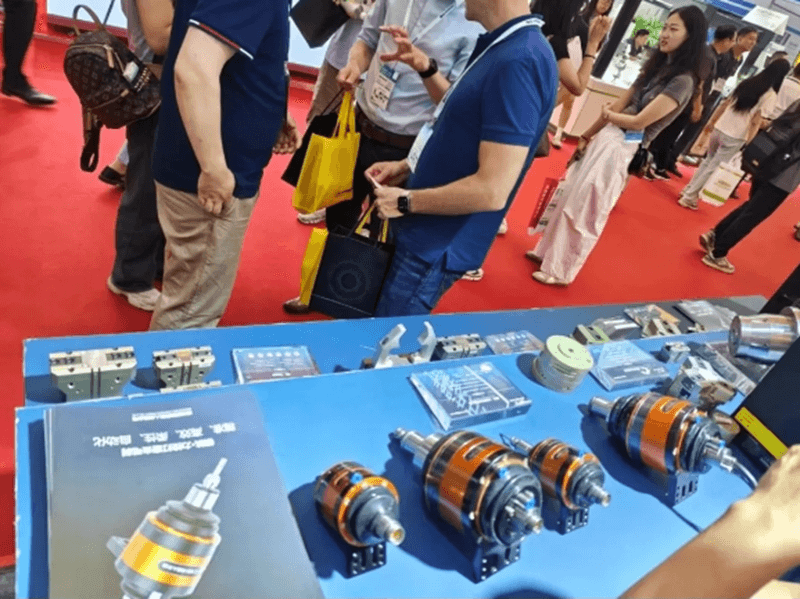

Core Product Display

Linghang Robot’s end-tool quick change devices and force control deburring tools, as well as control systems, are widely used in the automotive manufacturing industry. They have significantly improved production efficiency for renowned car brands such as Volvo, Volkswagen, Geely, BYD, and Seres, among others. At this exhibition, Linghang Robot demonstrated the application scenarios of its products in the automotive manufacturing industry, providing practical case studies for the industry.

Tool Quick Change Device

- High-strength alloy steel locking ensures connection precision and safety.

- The perfect combination of patented material technology and angled structure makes locking foolproof. Innovative RD connection technology ensures more stable data and signal transmission.

- Excellent LT fluid connection technology achieves millions of leak-free operations.

- Gas pressure loss self-locking function ensures safe operation.

- A full series of quick-change devices are available, with loads ranging from 5kg to 3000kg.

Force Control Deburring

- 360-degree radial force control floating, adapting to deburring of various complex parts.

- Patented low-friction structural design ensures sensitive and quick response of the tool.

- 1000-60000RPM replaceable electric spindle meets various process requirements, position repeatability accuracy of 1μm, accurately absorbing workpiece errors.

- Can replace various industrial grinding heads to meet specific deburring needs.

- Axial floating constant force grinding deburring: self-adaptive complex concave-convex surface grinding, precise force control, full-state active constant force compensation accuracy within ±0.5N.

Pneumatic Grippers

The perfect combination of multi-tooth guide rails and trapezoidal structure can bear greater torque and bending moments. The patented coating process ensures that the precision is almost intact after millions of grindings. The unique self-lubricating design allows for a longer maintenance-free use cycle.

Energy Docking Combination Board

Provides energy docking between the main station and the slave station, including electricity, data, I/O, gas, and liquid.

- Has an ultra-high plug-in life, high stability, and high reliability.

- Possesses strong current-carrying capacity and strong vibration and impact resistance.

Integrated Die-casting Deburring Innovative Technology Showcased

Addressing industry pain points such as large product sizes, widespread burr distribution, and significant product deformation for integrated die-casting deburring products, Linghang has innovatively launched an intelligent force control floating flexible deburring processing system, efficiently solving the deburring pain points of integrated die-casting parts and improving the quality and efficiency for the die-casting grinding industry.