With the rapid advancement of industrial automation technology, robot end-of-arm tool changers (commonly referred to as tool changers, quick-change devices, or quick couplers in the industry) are gradually becoming indispensable key equipment in the market. As a crucial component of industrial robot application systems, these tool changers offer several basic functions and advantages, market application case studies, and promising market prospects.

I. Basic Functions and Advantages of Robot End-of-Arm Tool Changers

Robot end-of-arm tool changers are quick and straightforward devices designed to facilitate the rapid and precise replacement of robotic end-effectors. Their core advantage lies in significantly enhancing production efficiency, reducing downtime, and lowering production costs. The main functions include:

- Rapid Replacement: Equipped with quick-lock and unlock mechanisms, these devices can complete tool changes in minimal time, drastically reducing downtime and enhancing production line flexibility.

- Time-Saving and Effortless: With a simple design and easy operation, these changers eliminate the need for complex tools or procedures, reducing the labor intensity and operational difficulty for workers.

- High Reliability: Made from high-quality materials and precision manufacturing processes, these devices boast high reliability and stability, ensuring long-term stable operation and reduced failure rates.

- Compatibility with Various Tools: These changers can accommodate a variety of tools and fixtures, such as grippers, suction cups, and welding torches, meeting diverse production needs.

- Ease of Maintenance: Compact in structure, these devices are easy to disassemble and replace, lowering maintenance costs and downtime.

II. Market Application Case Studies

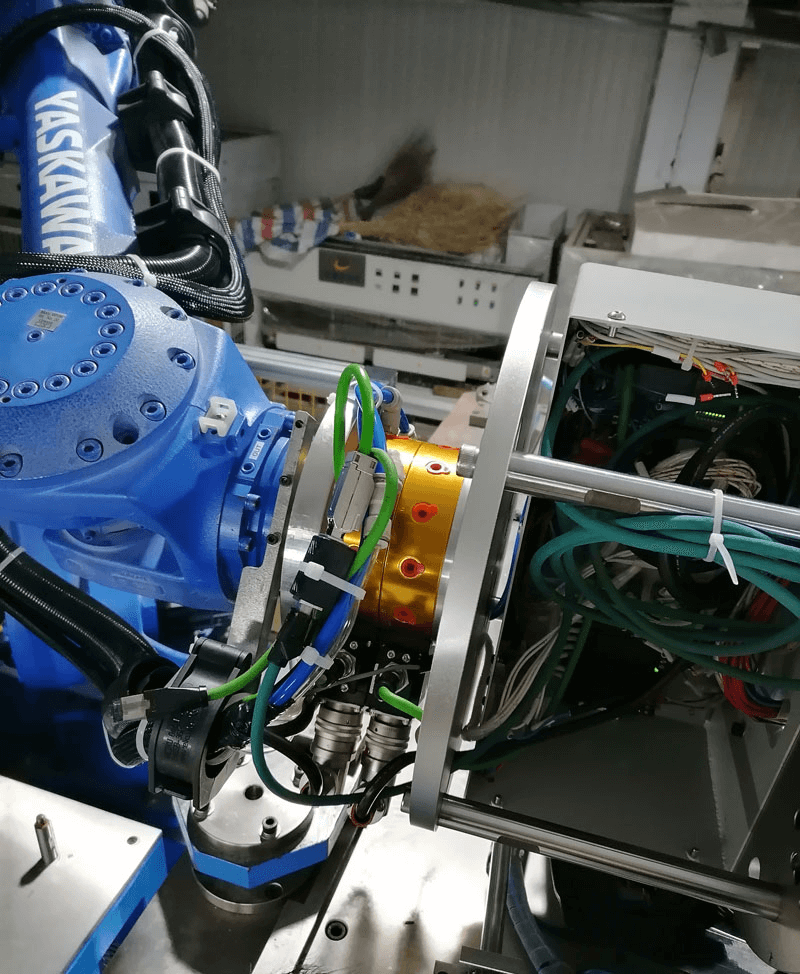

1. End-of-Arm Tool Changer by Linghang

The Linghang end-of-arm tool changer is a high-end product that integrates numerous cutting-edge technologies. Its design thoroughly considers the various challenges robots may encounter during operation. The core structure of the Linghang tool changer is precisely engineered to enable quick and accurate connection and disconnection with the robot’s end, significantly improving work efficiency. Additionally, its robust and adaptable characteristics ensure stable and reliable support for robots in various working environments.

Linghang tool changers are widely used in multiple fields, including automotive production lines, electronics manufacturing workshops, and heavy machinery assembly sites. On automotive production lines, robots frequently need to change different tools to perform welding, handling, and other tasks. The Linghang tool changer can respond quickly, ensuring the continuity and efficiency of the production line. In the electronics manufacturing sector, its high precision and stability meet the demands of precision assembly.

2. Broad Applications Across Various Industries

Robot end-of-arm tool changers are not limited to the aforementioned fields. They are also extensively used in automated spot welding, arc welding, machine tool loading and unloading, automated handling, 3C electronics, new energy batteries, semiconductors, stamping, inspection, assembly, grinding, packaging, and palletizing. These industries require high production efficiency and product quality. By enhancing the flexibility and efficiency of robots, end-of-arm tool changers bring significant economic benefits to these sectors.

III. Market Prospect Outlook

With the deepening of smart manufacturing and Industry 4.0, the market demand for robot end-of-arm tool changers will continue to grow. On one hand, there is an increasing urgency for enterprises to improve production efficiency and reduce production costs. On the other hand, the continuous advancement of robot technology provides strong support for the development of tool changers. In the future, robot end-of-arm tool changers will focus more on intelligent, automated, and integrated development to meet more complex and diversified production needs.

At the same time, with intensified market competition, enterprises will place greater emphasis on product quality and performance. Linghang Robotics, as a leader in the industry, will continue to increase research and development investment, enhance product competitiveness, and provide the market with more high-quality, efficient robot end-of-arm tool changer products.

IV. Conclusion

In summary, robot end-of-arm tool changers are essential equipment in the field of industrial automation, with broad market prospects and significant application potential. By improving production efficiency, reducing production costs, and enhancing the flexibility and reliability of production lines, robot end-of-arm tool changers are gradually becoming vital tools for enterprises aiming to achieve smart manufacturing. In the future, with continuous technological advancements and market expansion, robot end-of-arm tool changers will play an increasingly important role in various fields, contributing more to the development of industrial automation.