Supplies needed when cleaning and lubrication of the pneumatic tool changer: Cleaning wipes, Mobil XHP222 premium grease.

1. Keep the pneumatic tool changer in a safe location.

2. Loosen the master plate and tool plate.

3. Turn off all energized energy connections (such as electrical, air, etc.).

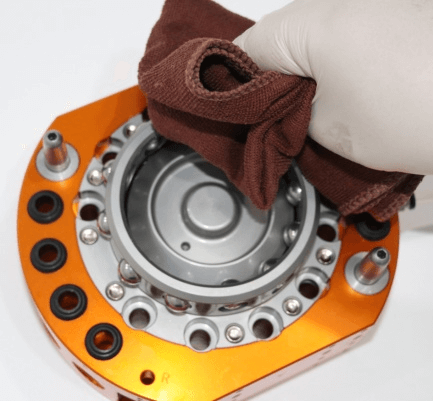

4. Use a clean cleaning cloth to thoroughly remove any lubricant and debris from the ball bearings, ball bearing housings, cams and dowel pins.

5. Use a clean cleaning cloth to remove all lubricant and debris from the inner surfaces of the ball bearing housing and cam.

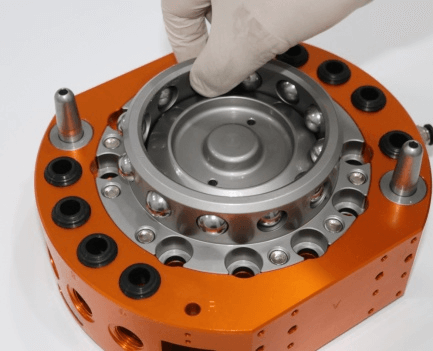

6. Inspect each ball bearing to ensure it moves freely in the bearing race. Clean up the sticky oil on the steel ball and make sure that the steel ball rotates freely in the hole.

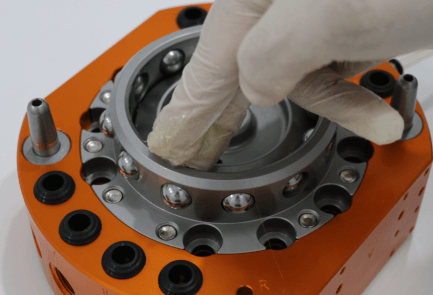

7. Apply a thick layer of grease to the balls, bearing races and dowel pins.

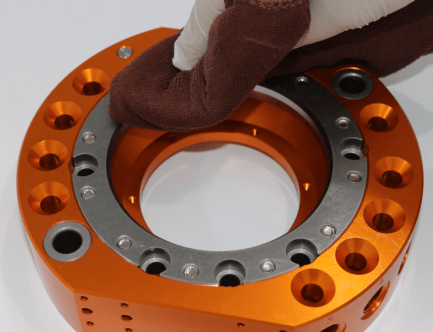

8. Thoroughly remove lubricant and debris from the bearing races and bushings from the tool disc with a clean cleaning cloth.

NOTE: No lubrication is required on the tool tray assembly.

9. Safely return to normal operation.