Linghang Robot Tool Changer (also known as quick-change device or tool changer) plays a crucial role in automobile assembly plants, especially on modern production lines where automation and robotics technologies are increasingly prevalent. Below are the main applications of Linghang Robot Tool Changer in automobile assembly plants:

1. Rapid replacement of robot end effectors:

The automotive manufacturing process involves various procedures such as welding, adhesive application, and assembly, each requiring different end effectors. Linghang Robot Tool Changer enables quick and accurate replacement of these end effectors, allowing robots to switch between different procedures rapidly, thereby enhancing the flexibility and efficiency of the production line.

2. Increased production efficiency:

Traditional tool replacement methods require manual operation, consuming time and labor. However, Linghang Robot Tool Changer achieves automated replacement, significantly reducing downtime and improving production efficiency. Moreover, it also reduces the risks of errors and damages caused by human factors.

3. Reduced production costs:

The application of Linghang Robot Tool Changer reduces downtime due to tool changes, improving equipment utilization. Additionally, it decreases labor and maintenance costs associated with tool changes, thereby lowering overall production costs.

4. Enhanced production line flexibility:

The diversity of automotive market demands requires production lines to adapt quickly to the production of different vehicle models and configurations. The application of Linghang Robot Tool Changer enables robots to easily meet the changing demands of different vehicle models and procedures, enhancing the flexibility and adaptability of the production line.

5. Ensuring production safety:

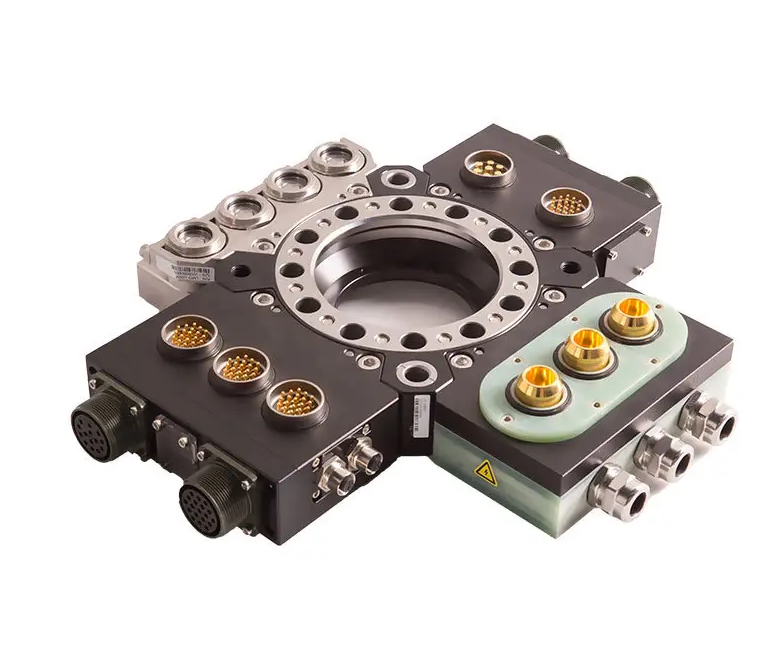

Linghang Robot Tool Changer features a safety locking mechanism to ensure a stable connection between the end effector and the robot during the replacement process. This prevents safety incidents caused by tool detachment or misoperation, ensuring production safety.

6. Improved product quality:

The high precision and stability of Linghang Robot Tool Changer ensure accurate installation and positioning of robot end effectors. This helps improve product quality and consistency, reducing quality issues caused by improper tool installation.

In automobile assembly plants, Linghang Robot Tool Changer is widely used in welding, assembly, inspection, and other production processes. It can be customized according to different production requirements, providing efficient, flexible, and safe production solutions for automobile assembly plants. Therefore, Linghang Robot Tool Changer holds a significant position in automobile assembly plants.