Material removal is one of the most frequently performed surface treatments in metal processing. Relying on manual deburring tasks can easily lead to rough and irregular surfaces of parts, increase the defect rate of products, and seriously affect the production efficiency and processing quality of enterprises.

Linghang material removal is an efficient and flexible automatic deburring tool. Equipped with a powerful electric motor, it is possible to quickly and easily automate demanding tasks such as deburring, stitching and flashing of various materials. The double-station processing mode can be adopted, and Material removal is used as a processing step, which avoids the time-consuming and laborious manual deburring, and has a high degree of automation, which improves the production efficiency of enterprises and improves product quality.

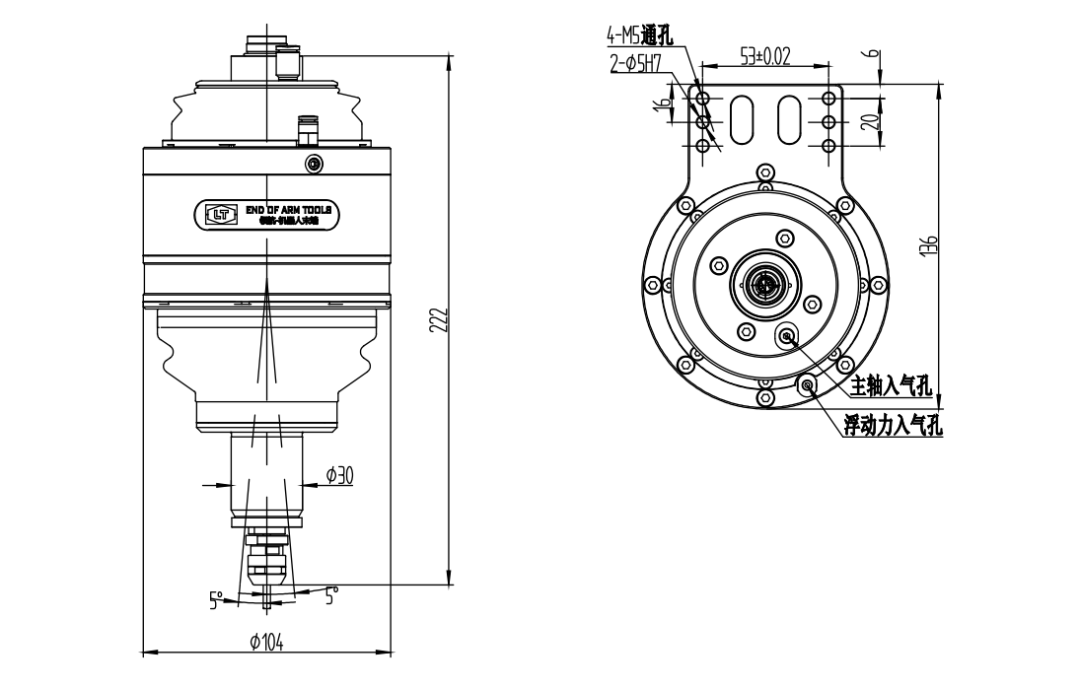

LT-FR030A Floating Grinding Spindle

Advantages for Material Removal Tools

- The contact between the tool and the workpiece can prevent the phenomenon of multi-cutting;

- The pressing force between the tool and the workpiece can be adjusted;

- It can eliminate workpiece errors and positioning errors, and ensure the contact between the tool and the workpiece;

- By adjusting the floating force, small burrs and relatively small nozzles can be removed at the same time;

Scope of Use

- Cast iron, steel, aluminum alloy resin, etc.

- processed flanging

- suture

- General Glitch

- Nozzle below 3mm

- Chamfer below C2

Floating Function

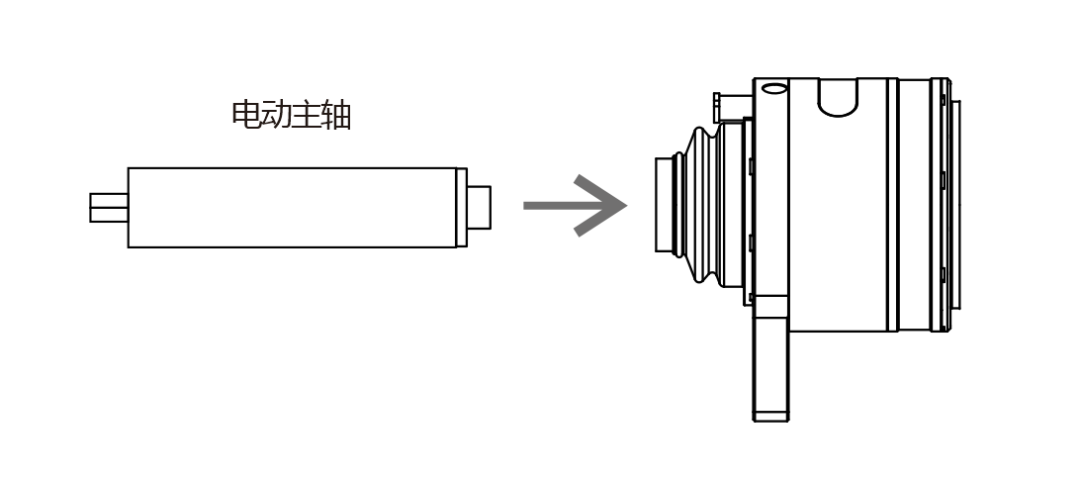

Combined Spindle

- Electric Spindle

- Others (30mm mounting holes)

Dimensions

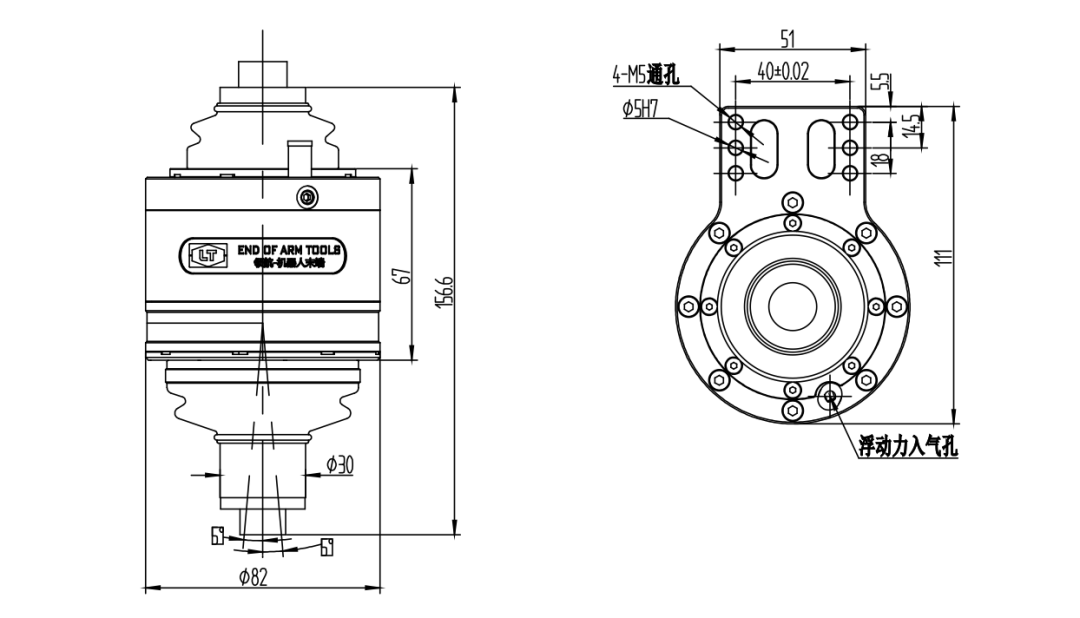

LT-FRC030A Floating Grinding Spindle

Advantages for Material Removal Tools

- The contact between the tool and the workpiece can prevent the phenomenon of multi-cutting;

- The pressing force between the tool and the workpiece can be adjusted;

- It can eliminate workpiece errors and positioning errors, and ensure the contact between the tool and the workpiece;

- By adjusting the floating force, small burrs and relatively small nozzles can be removed at the same time;

Scope of Use

- Cast iron, steel, aluminum alloy resin, etc.

- processed flanging

- suture

- General Glitch

- Nozzle below 3mm

- Chamfer below C2

Floating Function

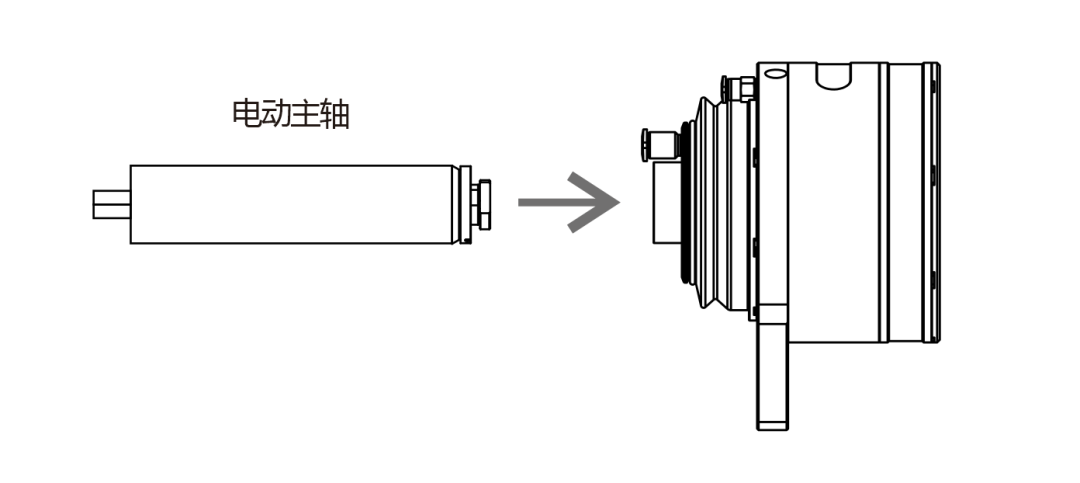

Combined spindle

- Electric Spindle

- Others (30mm mounting holes)

Dimensions