How many axes should an industrial robot have?

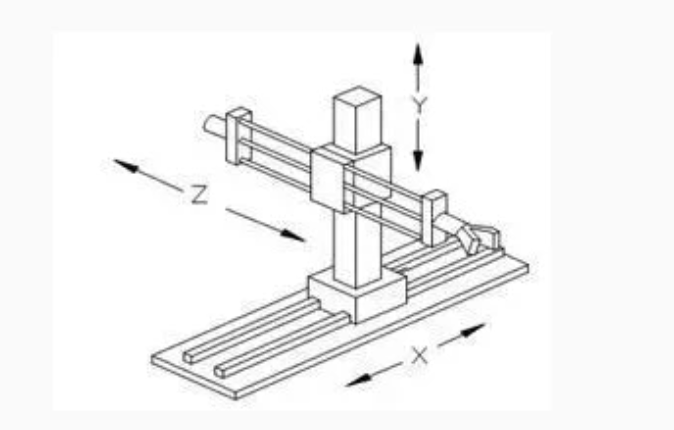

At present, industrial robots have been widely used in all walks of life, but we also found that industrial robots not only have different shapes, but also have different numbers of axes. The so-called axis of industrial robot can be explained by the professional term degree of freedom. If the robot has three degrees of freedom, it can move freely along the X, y and Z axes, but it can’t tilt or rotate. When the number of axes of the robot increases, it is more flexible for the robot. How many axes should industrial robots have?

Three axis robot is also called Cartesian coordinate or Cartesian robot. Its three axes can allow the robot to move along the three axes. This kind of robot is generally used in simple handling work.

Four axis robot can rotate along X, y and Z axes. Different from three-axis robot, it has an independent fourth axis. Generally speaking, SCARA robot can be considered as four axis robot.

Five axis is the configuration of many industrial robots. These robots can rotate through three space cycles of X, y and Z. at the same time, they can turn around by relying on the axis on the base and the axis with flexible rotation of the hand, which increases their flexibility.

The six axis robot can pass through the X, y and Z axes, and each axis can rotate independently. The biggest difference from the five axis robot is that there is an additional axis that can rotate freely. The representative of the six axis robot is youao robot. Through the blue cover on the robot, you can clearly calculate the number of axes of the robot.

Seven axis robot, also known as redundant robot, compared with six axis robot, the additional axis allows the robot to avoid some specific targets, facilitate the end effector to reach a specific position, and can more flexibly adapt to some special working environment.

With the increase of the number of axes, the flexibility of the robot also increases. However, in the current industrial applications, three-axis, four-axis and six axis industrial robots are used most. This is because in some applications, high flexibility is not required, three-axis and four-axis robots have higher cost-effectiveness, and three-axis and four-axis robots also have great advantages in speed.

In the future, in the 3C industry that needs high flexibility, the seven axis industrial robot will have a place to play. With its increasing accuracy, it will replace manual assembly of precision electronic products such as mobile phones in the near future.

Seven axis industrial robot is better than six axis industrial robot

Where’s Qiang?

Technically, what are the problems with six axis industrial robots and what are the strengths of seven axis industrial robots?

(1) Improve kinematic characteristics

In the kinematics of robot, three problems make the motion of robot very limited.

The first is the singular configuration. When the robot is in a singular configuration, its end effector can not move in a certain direction or apply torque, so the singular configuration greatly affects the motion planning.

The sixth axis and the fourth axis of the six axis robot are collinear

The second is joint displacement overrun. In the real working situation, the angle range of each joint of the robot is limited. The ideal state is plus or minus 180 degrees, but many joints can’t do it. In addition, the seven axis robot can avoid too fast angular velocity movement and make the angular velocity distribution more uniform.

Motion range and maximum angular velocity of each axis of Xinsong seven axis robot

Third, there are obstacles in the working environment. In the industrial environment, there are various environmental obstacles in many occasions. The traditional six axis robot can not only change the attitude of the end mechanism without changing the position of the end mechanism.

(2) Improve dynamic characteristics

For the seven axis robot, using its redundant degrees of freedom can not only achieve good kinematic characteristics through trajectory planning, but also use its structure to achieve the best dynamic performance.

The seven axis robot can realize the redistribution of joint torque, which involves the problem of static balance of the robot, that is, the force acting on the end can be calculated by a certain algorithm. For the traditional six axis robot, the force of each joint is certain, and its distribution may be very unreasonable. However, for the seven axis robot, we can adjust the torque of each joint through the control algorithm to make the torque borne by the weak link as small as possible, so that the torque distribution of the whole robot is more uniform and more reasonable.

(3) Fault tolerance

In case of failure, if one joint fails, the traditional six axis robot can not continue to complete the work, while the seven axis robot can continue to work normally by readjusting the redistribution of the speed of the failed joint (kinematic fault tolerance) and the torque of the failed joint (dynamic fault tolerance).

Seven axis industrial robot products of international giants

Whether from the product point of view or from the application point of view, the seven axis industrial robot is still in the preliminary development stage, but major manufacturers have pushed relevant products in major exhibitions. It can be imagined that they are very optimistic about its future development potential.

– ABB YuMi

On April 13, 2015, abb officially launched the world’s first dual arm industrial robot Yumi that truly realizes man-machine cooperation to the market at the Industrial Expo in Hanover, Germany.

Each single arm of Yumi has seven degrees of freedom and the body weight is 38 kg. The load of each arm is 0.5kg, and the repeated positioning accuracy can reach 0.02mm. Therefore, it is especially suitable for small parts assembly, consumer goods, toys and other fields. From the precision parts of mechanical watches to the processing of mobile phones, tablet computers and desktop computer parts, Yumi is no problem, which reflects the excellent characteristics of the redundant robot, such as expanding the reachable workspace, flexibility, agility and accuracy.

-The more intelligent, the more Presto mr20

As early as the end of 2007, Na bueryue developed the seven degree of freedom robot “Presto mr20”. By adopting the seven axis design, the robot can perform more complex workflow and move in a narrow working area like a human arm. In addition, the torque of the front part (wrist) of the robot has increased to about twice that of the original traditional six axis robot. The torque of the standard configuration is 20kg. By setting the action range, it can carry up to 30kg of articles, the working range reaches 1260mm, and the repeated positioning accuracy is 0.1mm. By adopting the seven axis structure, mr20 can operate from the side of the machine tool when taking and placing workpieces on the machine tool. In this way, the efficiency of preparation and maintenance in advance is improved. The space between machine tools can be reduced to less than half of the traditional six axis robot.

A typical redundant arm

Although China has made some achievements in redundant degree of freedom robots, it mainly stays in the stage of academic papers, scientific research reports and experimental prototypes, and has not achieved real product development, which undoubtedly restricts the pace of robot products in China towards high-end industrialization.

As a leading enterprise of domestic industrial robots, Xinsong took the lead in releasing the first domestic seven axis industrial robot at the 2015 Industry Expo. Its own weight is 29kg, load is 5kg, repeated positioning accuracy can reach 0.02mm and working radius can reach 800mm. It has the functions of rapid configuration, traction teaching, visual guidance, collision detection and so on. It is especially suitable for flexible production lines with compact layout and high accuracy, and meets the needs of industrial operations such as precision assembly, product packaging, grinding, detection, loading and unloading of machine tools.

At present, the vast majority of China’s industrial robot enterprises have not released seven axis industrial robot products. Some of them say they are developing related products and will come out within this year, while others say they are concerned about seven axis industrial robot products, but have not planned to design and develop related products.

China’s robot industry has made great progress in the theoretical research of seven axis industrial robot, but there is still a big gap between China and foreign countries in terms of commercial products. The main reasons are as follows:

First, the ability of independent innovation is weak. Lacking the original achievements and innovative ideas of core and key technologies, the overall technology of industrial robots in China lags behind the advanced level of foreign countries by more than ten years.

Second, the profitability of enterprises is low and there is a shortage of R & D funds. The lack of core component technology led to high production costs. In addition, foreign manufacturers reduced prices one after another. In 2015, more than 70% of enterprises’ ontology business was in a state of loss.

According to experts, the overall technology of industrial robots in China lags behind the advanced level of foreign countries by more than ten years. The emergence of domestic seven axis industrial robots shows that our R & D of industrial robot technology is accelerating, but we should have a clear understanding that the gap really exists. If we want to overtake in a corner, we need to overcome the core technical difficulties as soon as possible, and also pay attention to the R & D of next-generation technologies such as artificial intelligence, perception, recognition, drive and control.