Robot Tool Changer has been widely applied and practiced in multiple industries. Here is a detailed explanation of its main application points and practical achievements:

Application Fields

Automotive Manufacturing: Robot Tool Changer technology is widely used on automotive production lines, enabling quick changes of fixtures for efficient and accurate assembly of automotive parts. This technology enhances production efficiency, reduces production costs, and ensures product quality.

Electronics Manufacturing: In the electronics manufacturing process, Robot Tool Changer is used for the placement and inspection of various electronic components. By quickly changing different fixtures and tools, Robot Tool Changer achieves high-precision and high-speed assembly and inspection of electronic components, improving production efficiency and quality.

Food Processing: Robot Tool Changer assists robots in food packaging and processing, allowing for the quick change of different fixtures and tools to achieve efficient and accurate food processing and packaging. This improves production efficiency and product quality.

Logistics: In the logistics industry, Robot Tool Changer is used for cargo handling and sorting. By quickly changing different fixtures and tools, it enables efficient and accurate cargo handling and sorting, enhancing logistics efficiency and accuracy.

Practical Achievements

Quick Change: Robot Tool Changer devices can quickly and accurately change fixtures or tools, significantly reducing downtime caused by fixture changes and increasing production efficiency.

Cost Reduction: By simplifying production processes and reducing manual intervention, Robot Tool Changer technology lowers production costs for enterprises.

Safety Assurance: The use of automation technology by Robot Tool Changer avoids potential safety accidents that could occur during manual fixture changes, thereby improving operational safety.

Increased Flexibility: Robot Tool Changer can adapt to different fixtures and tasks, enhancing the flexibility of robots, allowing them to easily handle various complex operations.

Improved Precision: Through precise control and positioning, Robot Tool Changer improves the accuracy and consistency of fixture changes, reducing errors and defect rates.

Technical Features

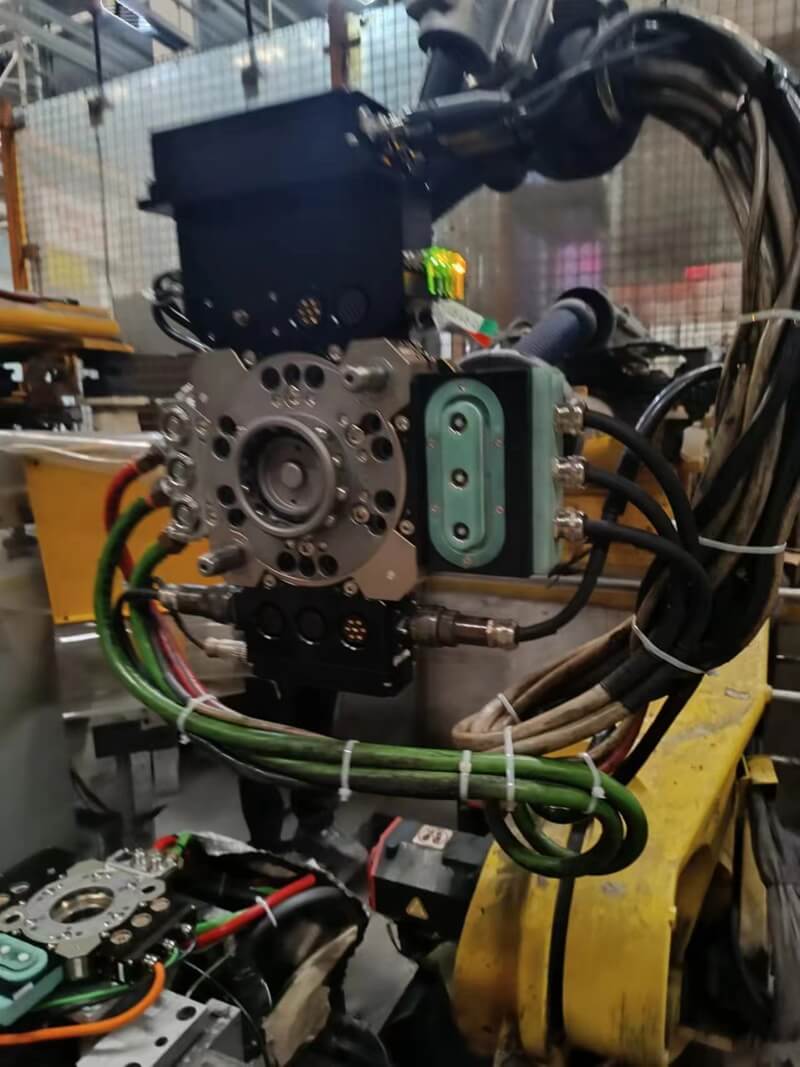

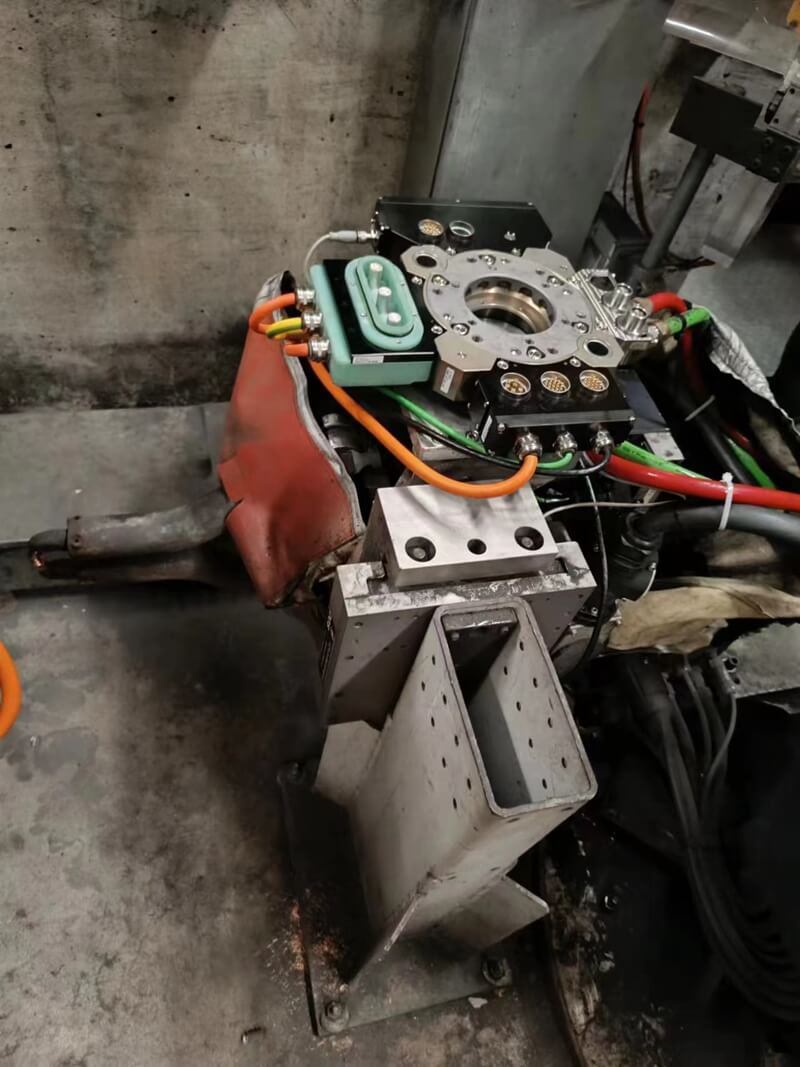

Standardized Interface Design: By establishing uniform interface standards and specifications, different end effectors can be easily installed on the robot, simplifying the change process.

Quick Locking Mechanism: This mechanism enables a secure connection between the end effector and the robot in a short time, allowing locking and unlocking processes to be completed with simple operations.

Ease of Integration and Expansion: Robot Tool Changer can be integrated with various types of robots to achieve quick and accurate tool or fixture changes. Additionally, this system can communicate and control other equipment on the production line, realizing automation and intelligence of the entire production line.

In summary, Robot Tool Changer demonstrates significant advantages in improving production efficiency, reducing costs, ensuring safety, enhancing flexibility, and improving precision through its wide application and practice in various industries. With continuous development and refinement of technology, Robot Tool Changer is expected to play an increasingly important role in the field of industrial automation in the future.