A pressure transducer is a device or apparatus that can sense pressure signals and convert them into usable output electrical signals according to a certain rule. Pressure transducers typically consist of pressure-sensitive elements and signal processing units. Depending on the type of pressure being measured, pressure transducers can be classified as gauge pressure transducers, differential pressure transducers, and absolute pressure transducers.

Pressure transducers are one of the most widely used sensors in industry. Pressure transducers (pressure transmitters) are used to measure the pressure in pipes and containers. Pressure can be measured using methods such as resistance strain gauges, semiconductor strain gauges, piezoresistive, inductive, capacitive, magnetic control, ceramic piezoelectric, pressure sensors, as well as U-tube pressure gauges that indicate atmospheric pressure directly by measuring liquid height. There are also hand-operated pressure pumps (calibrators) used for on-site pressure calibration.

For strain gauge pressure sensors, the strain gauge is bonded to the measuring body, and when the measuring body is subjected to pressure, it undergoes deformation which causes a change in the resistance or internal characteristics of the strain gauge. This results in a change in the voltage applied to the strain gauge, which is then extracted using a bridge circuit, amplified, and output as a corresponding measurement signal. The measurement principle of pressure sensors is similar to that of liquid level sensors. For pressure sensors that use a pressure measuring tube, mechanical deformation occurs when the measuring tube is filled with the tested liquid, which drives the measuring element, such as a potentiometer, to produce an electrical signal proportional to the pressure.

There are pressure gauges with different functions, such as corrosion resistance, earthquake resistance, high temperature resistance, and diaphragm, oil-filled, earthquake-resistant, and high-temperature resistant pressure gauges. In order to meet different pressure measurement ranges, there are pressure gauges with positive pressure, negative pressure, differential pressure, positive and negative pressure ranges, etc. For measuring different media, there are also pressure gauges with different specialized uses. Differential pressure pressure transmitters can measure the pressure difference between two pipelines, while gauge pressure transmitters can only measure the pressure at one point in the pipeline.

Pressure sensors that only output switching signals are called pressure switches or pressure relays. The pressure actuation value of a pressure switch can be set as required, and when the pressure reaches the actuation pressure, the contact switch is triggered. A pressure gauge with contacts is called an electrical contact pressure gauge, and its principle is that when the pressure is greater than the high set value, one contact is triggered, and when the pressure is less than the low set value, another contact is triggered.

Principles of Sensors

- Resistive Pressure Sensor

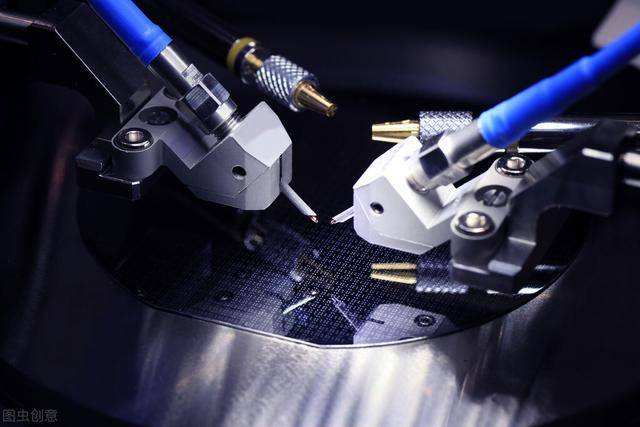

The metal resistive strain gauge is one of the main components of a resistive strain sensor. The working principle of the metal resistive strain gauge is the phenomenon that the strain resistance adsorbed on the substrate material changes with the mechanical deformation, commonly known as the resistive strain effect.

- Ceramic Pressure Sensor

The ceramic pressure sensor is based on the resistive effect. The pressure directly acts on the front surface of the ceramic diaphragm, causing the diaphragm to produce slight deformation. Thick film resistors are printed on the back of the ceramic diaphragm and connected into a Wheatstone bridge. Due to the resistive effect of the pressure-sensitive resistor, the bridge produces a voltage signal that is highly linear with the pressure and directly proportional to the excitation voltage. The standard signal is calibrated to 2.0/3.0/3.3mV/V according to the different pressure ranges and is compatible with strain-based sensors.

- Diffused silicon pressure sensor: The working principle of the diffused silicon pressure sensor is also based on the piezoresistive effect. The pressure of the measured medium directly acts on the diaphragm of the sensor (made of stainless steel or ceramics) based on the piezoresistive effect, causing the diaphragm to produce a displacement proportional to the medium pressure. This changes the resistance value of the sensor, which is detected by an electronic circuit and converted into a standard measurement signal corresponding to the pressure.

- Sapphire pressure sensor: Using the strain gauge principle, a silicon-sapphire semiconductor sensing element is used, which has unparalleled measurement characteristics. Therefore, the semiconductor sensing element made of silicon-sapphire has good working characteristics even under high temperature conditions and is not sensitive to temperature changes. Sapphire has strong radiation resistance. In addition, the silicon-sapphire semiconductor sensing element has no p-n drift.

- Piezoelectric pressure sensor: The piezoelectric effect is the main working principle of the piezoelectric pressure sensor. The piezoelectric sensor cannot be used for static measurement because the charge generated by external force is only preserved when the circuit has an infinite input impedance. In reality, this is not the case, which determines that the piezoelectric sensor can only measure dynamic stress.