In the era of “Industry 4.0”, industrial robots play a pivotal role in the field of manufacturing. Traditional industrial robots are designed based on predetermined tasks, and their fixed structure shows limitations. Most industrial robots can only complete one operation in the automated production process.

In the actual production process, a product needs to go through multiple complex processes. The robot at each station is responsible for a single job. The enterprise needs to configure multiple robots to complete the entire process. Such an automated production line requires more robots. Occupying a large working space, the production and manufacturing costs of enterprises have increased significantly. Therefore, the assembly line robot operation is not suitable for small batch production, the product is not easy to move, and the working space is limited. On the contrary, it is more feasible for a single robot to achieve multiple operation tasks.

Linghang robot tool changer is a flexible device that increases the use of multiple execution tools for a single industrial robot. One robot side can be used with multiple tool sides. During the production process, the robot can release the current tool according to the instruction requirements. Executing tools, locking the tool tray and end-executing tools required for the next process, and completing the rapid replacement of the executing tools within a few seconds, increasing the flexible manufacturing of the robot production line and the utilization rate of the robot. It is widely used in fast switching of end tools such as spot welding tongs, end pickers, grippers, punching tongs, lasers, burr cleaning tools, vision devices, ultrasonic welding guns, etc.

How Robot Tool Changer discs work

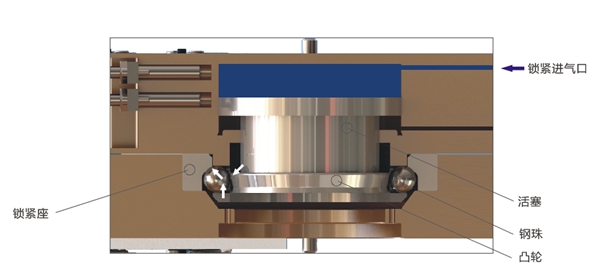

1. Locked state

The gas enters the robot tool changer through the locking air inlet, pushes the piston to move, pushes out the steel ball, and locks the locking clamp.

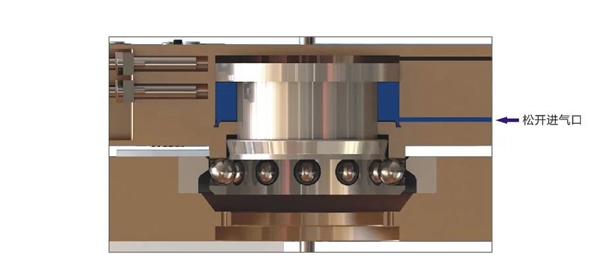

2. Release state

The gas enters the robot tool changer by releasing the air inlet, pushes the piston to move, and the steel ball retracts.

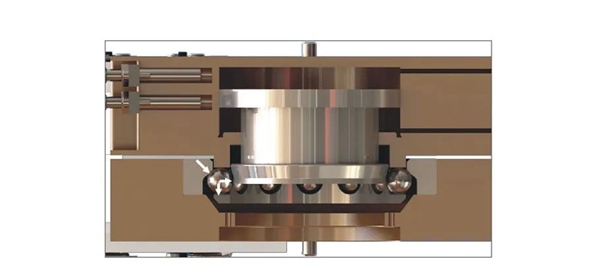

3. Gas loss protection

When the gas is cut off unexpectedly, the steel ball moves from the locking platform to the insurance platform, and remains in the insurance platform position of the cam, and the thrust of the spring can effectively ensure that the tool plate will not fall off.

Series of robot tool changer , with loads ranging from 5KG-2300KG, suitable for all brands of industrial robots. The products have successively passed ISO9001 quality certification and EU CE safety certification. The locking mechanism and positioning pins are made of high-strength stainless steel, which ensures that the gun changer can still maintain high precision after millions of times of opening and closing wear; Loss of pressure, the locking mechanism loses the air pressure locking force, the spring will still keep the gun changer cam in the locked position; the safety parking system, when the tool quick changer works normally, even if the industrial robot wrongly outputs the opening command to the solenoid valve module, The tool changer also does not perform an opening operation.