Today, the term “robot toolchanger” covers more ground than ever before. The concept includes traditional ATCs, the latest of which offer a variety of new technologies and features designed to improve processing operations. In addition, the description can be applied to robotic equipment that provides assistance in the workshop by automatically replacing the end-effector.

On the traditional side, stores are benefiting from a number of ATC-related developments. One was the introduction of inertial active control on machine tools at Makino Inc. in Mason, Ohio. As a standard feature of Makino’s annular tool library, IAC is designed to reduce non-cutting time.

“If we can do something to eliminate non-production time, it opens up capacity in machines and makes them more valuable to customers,” said product marketing manager.

IAC automatically senses the total mass in the ATC tool library and adjusts acceleration and deceleration parameters to optimize the rotation speed of the tool library, reducing the “seek time” for robot tool changer.

“The faster we can get the tool out of the library and into the ready station, the better we’re going to do from a cycle time perspective and the more non-cutting time we can eliminate,” Ward said.

Rotation speed of this 60-tool ring magazine is optimized using Inertia Active Control technology that senses the total mass in the magazine. At the top center is the digital camera for the Vision BTS system, which evaluates pictures from the camera to instantly detect broken tools.

Another system that now comes standard on Makino’s horizontal machines is Vision BTS, a noncontact tool-breakage detection system. Vision BTS features a high-speed digital camera mounted inside the tool magazine and aimed at the ready station of the tool change system, as well as an LED light source. When a tool removed from the spindle reaches the magazine, the LED flashes like the flash on a camera to produce a silhouette of the tool. The camera takes a picture of that silhouette, which then is measured to determine the condition of the tool. He said Vision BTS can quickly assess the condition of tools down to 3 mm (0.118″) in diameter.

“In a fraction of a second,” Ward said, “you can have 100% confidence that the tool did not break while it was machining.”

Additionally, Vision BTS works with a toolchanger to set the proper speed for each tool change. This is based on a rough determination of the mass of each tool, which is obtained by calculating the cross-sectional area of the tool silhouette and multiplying that by the length of the silhouette and the density of the tool material.

Vision BTS “can automatically set the tool change speed so your operators don’t have to spend a lot of time optimizing the program as they put a new tool in,” Ward said.

Door Developments

With the rough length of a tool obtained from the silhouette image, the system also can automatically customize the distance that the ATC shutter door must open for each tool. Separating the tool magazine from the inside of the machine, the shutter door slides back and forth to allow the passage of tools during the tool change process.

“We can set the shutter door to only open far enough to allow that tool to come through during the tool change,” Ward said. “So if it’s a very short tool, the shutter doesn’t have to open very much.”

This saves a fraction of a second of tool change time, he said, and minimizes exposure of the ATC magazine to the dirty machining environment.

To boost reliability, all Makino horizontal machining centers now are equipped with servo-driven ATC shutter doors. Ward pointed out that the traditional way to actuate these doors is with air cylinders, which function fairly well when new but suffer over time from exposure to unclean manufacturing environments, resulting in slower performance, maintenance problems and downtime.

By contrast, Makino’s system, which includes a ballscrew, as well as a servomotor, provides “very consistent performance from day one to (many) years down the road,” he said. “I think our competitors look at it as an expensive solution. We look at it as what we need to do to provide reliability for our customers.”

In addition to these standard features, Makino now offers MHmax, an optional predictive maintenance software and sensor package designed to eliminate unplanned downtime. Among other things, MHmax can monitor tool change handoff position and ATC timing. Misalignment of handoff position causes a tool to bang into the spindle, so MHmax monitors the forces on the machine during a tool exchange and can alert an operator when handoff position is less than optimal. The system also signals the operator if the time taken to move a tool from the ring to the ready station starts to be longer. This is an indication that the ATC is wearing and needs to be adjusted, Ward said.

Partly to satisfy demands from machining operations in some industries for access to more tools, he is starting to see a move mainly in the European market toward central tool storage and delivery systems. In such systems, several machines are linked to a central magazine that may hold up to 1,000 tools, which are grabbed and delivered to the machines on an as-needed basis by automation equipment.

Machine shops increasingly are employing collaborative robots, also known as cobots, because “the price point is coming down and the ease of use for novice customers is going way up,” said Baron Kendrick, standard toolchanger product manager at ATI Industrial Automation Inc. in Apex, North Carolina.

Different from the ATCs commonly found on shop floors, ATI Industrial Automation’s automatic toolchangers allow users to swap tools at the end of robot arms, eliminating the need to have a dedicated robot for each process that gets a robotic assist.

Instead, “you can have a single robot do different processes by changing tools,” Kendrick said. “So now the robot is staying busier and paying off the investment faster.”

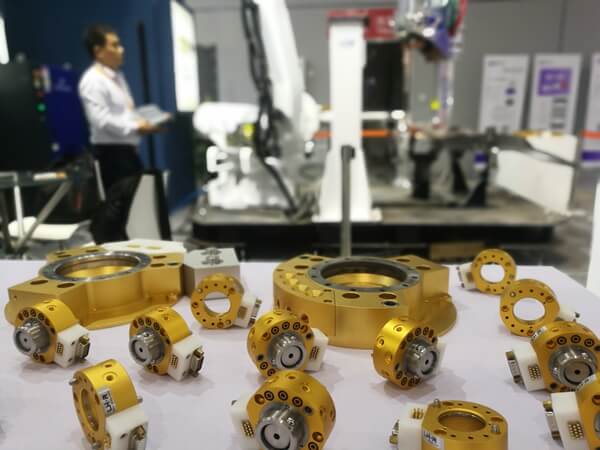

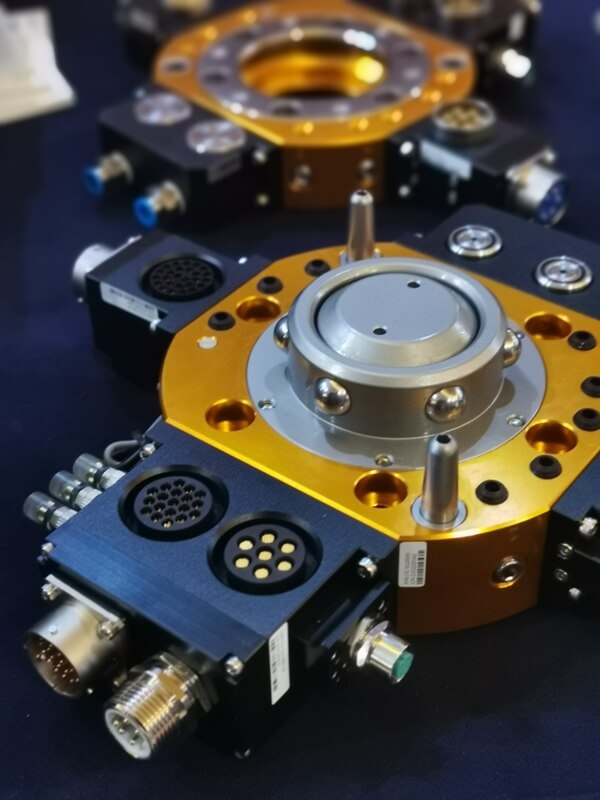

Essentially a mechanical coupling device, a robotic toolchanger consists of an A half, which is permanently attached to the robot, and a B half, an adapter plate that mounts to whatever tool is needed for a particular process. Examples of these include grippers, spot welders and deburring spindles. A toolchanger simply uncouples a B half from one tool and couples the half to another tool.