With the vigorous promotion of “made in China 2025” and intelligent manufacturing, more and more manufacturing enterprises begin to use robots for processing and manufacturing. It can enable a single robot to exchange and use different end effectors in the process of manufacturing and equipment to increase flexibility. Zhengzhou LT robot Co., Ltd. provides a fully automatic quick change device for robot end effector. Firstly, the structure of the quick change is designed according to the use requirements and key performance of the ROBOT TOOL CHANGER ; The results show that the maximum stress is far less than the allowable stress of the material, which meets the strength requirements. The quick change does not need additional power for assembly, and has a certain elasticity.

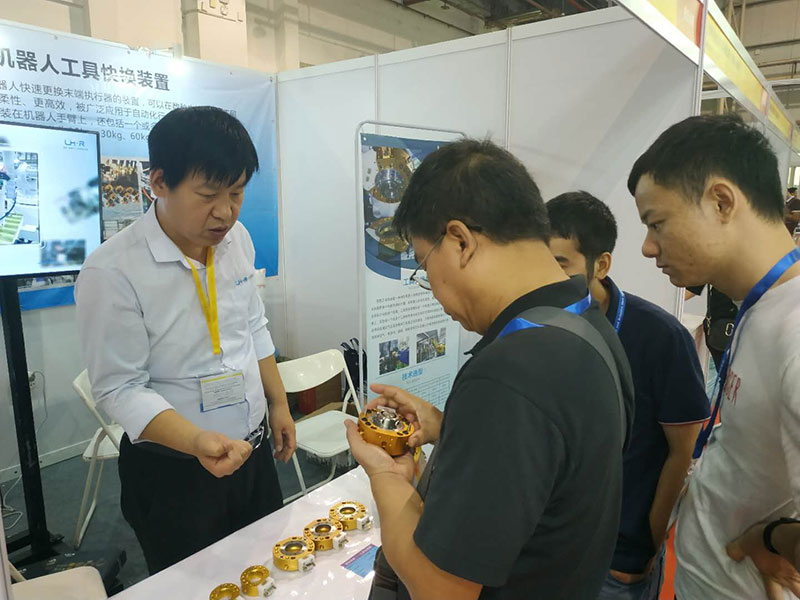

At present, foreign countries are relatively advanced in robot automatic replacement technology, with early start and high degree of specialization, but the price is expensive, the technology is not external, and the products produced have their own characteristics. The tool quick change introduced by Zhengzhou pilot is widely used in automobile manufacturing, medical treatment Aviation, food and other automation industries.

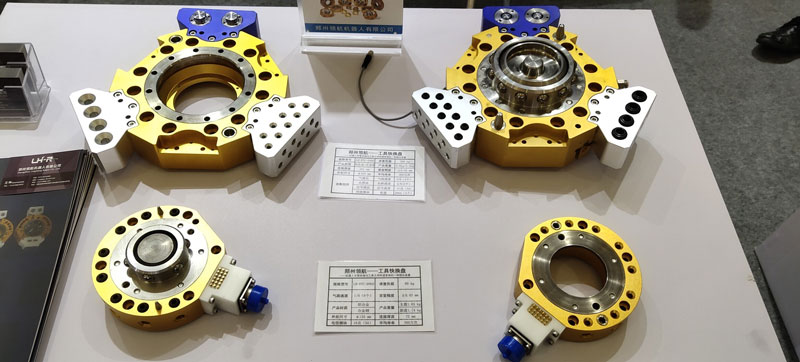

The robot quick change device produced by LT can enable the robot to replace different end effectors, and connect different media (such as gas, electrical signal, liquid, etc.) from the robot arm to the end effector, so as to increase the flexibility of the robot to Polish furniture. The robot quick change usually includes the driving disc connected with the robot arm, the tool disc connected with the end effector, the manipulator adaptation plate, the tool adaptation disc and other auxiliary components.

The tool quick change has the function of gas pressure loss protection – most of the tool quick change devices use pneumatic locking mechanism (the pilot robot has an electrically driven tool quick change device). If the air source is interrupted during commissioning and application, the robot side of the tool quick change device must keep locking the tool side. The pilot robot relies on its own mechanical design The gas pressure loss protection function can be realized without spring; The spring itself has clip and aging, so it is very unreliable to realize the protection function of gas pressure loss;

The tool quick change device produced by LT is divided into robot side and tool side. The robot side is installed on the front arm of the robot, and the tool side is installed on the executive tool (tools are welding tongs, grippers, etc.). The tool quick change device can quickly realize the connection of electricity, gas and liquid between the robot side and the executive tool. One robot side can be used with multiple tool sides according to the actual situation of the user, so as to increase the flexible manufacturing of the robot production line, increase the efficiency of the robot production line and reduce the production cost.