Now, with the development of industrial intelligent manufacturing, more and more factories have launched industrial robots. If a robot body is directly connected with tooling fixtures, it can only carry out one task, which greatly limits the use efficiency of industrial robots.

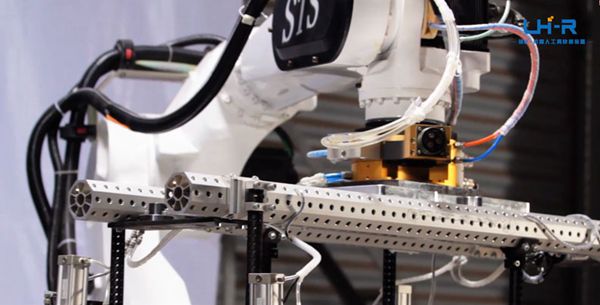

The robot tool changer produced by Linghang robot Co., Ltd. can effectively solve this problem. It includes a robot side to be installed on the robot arm, and one or more tool sides to be installed on different end actuators respectively. It uses electrical signals and compressed air to complete the communication between the master plate and tool plate.

How can a variety of robot models be used quickly?

Ranging from 10kg to 300kg, they represent the bearing size of the quick change plate respectively.

When selecting the model, we should first consider the load of the industrial robot itself. The model of quick change plate must be greater than or equal to the load of the industrial robot itself. For example, my factory now uses irb6700-155 robot with a load of 155kg, so which model should I choose?

LT has two models near 150kg: 120kg and 200kg. According to the above principles, 200kg ROBOT TOOL CHANGER should be selected.

The channel and signal required by the fixture shall be inspected.